Aluminum wiring: weighed all the pros and cons

Benefits

From the very beginning, it should be noted that aluminum wiring is not the most reliable and high-quality and cannot boast of any outstanding merits, compared to other types. But, nevertheless, it is precisely this type of electrical wiring that was carried out in most old houses and apartments (Khrushchev). And so, let us first start with the advantages of this type:

- lightness (aluminum has a lower weight compared to other metals that are used in electricity as conductors);

- corrosion resistance (metal when exposed to air instantly oxidizes, forming a film that protects the rest of the wire from further corrosion).

According to chapter 7.1. PUE, clause 7.1.34. wiring must be carried out with cables with copper conductors. Aluminum cables and wires with a cross section lived from 2.5 square meters. mm is permissible to use when connecting individual electrical appliances that relate to engineering electrical equipment or when connecting powerful electrical equipment with an aluminum cable with a cross-section of conductors from 16 square meters. mm

In accordance with the foregoing, today aluminum is most often used in electrical wiring in power cables of large cross-section (tens and hundreds of square mm), where the weight and cost of the material is a very important factor. The savings in this case can be very significant - aluminum is cheap metal, and the amount of material used will still allow you to spend less than other types of wires. A true example of this is huge popularity. SIP wireswhose cores are made of aluminum. For aerial cable routing, this conductor is one of the most suitable. Moreover, according to the PUE chapter 2.1. Section 2.1.14 and Chapter 7.1. Section 7.1.131, the cross-section of the aluminum cable for branching through the air must be at least 16 square meters. mm

Nevertheless, in new buildings, aluminum wiring has not been used for a long time, and there are reasons for this.

disadvantages

There are quite a few disadvantages to this type of wire:

- The fluidity of the metal. Aluminum has the ability to stretch, this has a negative effect in the case of screw connection of wires. The wire connections weaken over time, begin to warm up, oxidize and burn, up to the complete loss of contact.

- Fragility of aluminum. In the process of aging and long service life, the wires will simply break, especially with frequent loads and overheating.The same must be taken into account when you re-patch old twists - when you unwind and re-twist them, there is a big risk that your core will break.

All of these shortcomings in one way or another in the end result lead to the fragility of the entire power supply system and short life. When asked how long aluminum wiring serves, you will get a comprehensive answer - as long as its insulation will last. Depending on the conditions and method of laying, the service life is 5-25 years.

Some important facts

So, so that you, what is the danger of aluminum wiring, we recommend that you familiarize yourself with the following facts:

- In accordance with international standards, aluminum wiring has long been recognized as a potential fire hazard.

- More than once recorded cases fire wiringthat caused the death of people.

- In houses and apartments where an aluminum power grid was used, fire cases were recorded 55 times more than with other electrical wiring.

- This type of wiring is still approved for use, but only in installations and houses built before 2001, according to chapter 7.1. PUE. paragraph 7.1.34.

- In order to prevent fire, it is forbidden to connect copper and aluminum wires with twisting and some other methods. How to connect aluminum and copper together, read the article: https://my.electricianexp.com/en/kak-soedinit-alyuminievyj-provod-s-mednym.html.

All these factors can cause a fire in the home network and as a result of a fire in a house or apartment. You can clearly see how dangerous this type of wiring is, in the video below:

That is why we strongly do not recommend using this type of wire at home. Especially if you want conduct wiring in a wooden house or in the country, which you rarely visit.

Is it worth changing the old wiring

We will answer this question unequivocally - Yes! One of the nuances that speak in support of replacing aluminum wiring is the maximum load that it can withstand. Even one hundred percent functional wiring, which was used before, in the modern world will not withstand the loads. And to install a more powerful wiring (with a large cross section) is prohibited, as this can lead to a fire.

Copper cable can withstand modern loads, more reliable and fire resistant. Therefore, the replacement of aluminum wiring is certainly worthwhile. Especially if you choose the best option.

Another hindering process could be the financial side of the issue. Replacing all electrical wiring in the house or an apartment can result in a tidy sum. Also, to completely replace the old wiring, it will be necessary to re-drill all the living quarters. If you are not a "jack of all trades" and you can’t do the job yourself, in this case there is a way out - you can make a couple of separate lines with a copper cable so that they take on the main load of the mains, and use the remaining aluminum lines only for lighting. In addition, new wires can be hidden under the baseboard or in the doorposts. Thus, you will reduce the load on the aluminum wiring and make it safer and more reliable.

If you take up this laborious process yourself, get ready for considerable waste. Firstly needed wiring tool. Well, if you have one or have friends / relatives. Otherwise, it is a waste again. Secondly, set aside time for this. In the modern world, even this is difficult. And thirdly, be prepared for the fact that you can spend less time on repairs than on cleaning after it.

But still there are life situations when it is impossible to completely or partially replace the wiring. In this case, you need to know the most important rules for using aluminum wiring.

Return to apartments and houses in 2019

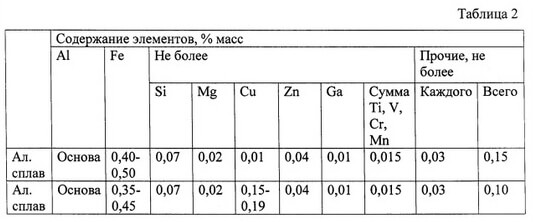

It is worth noting that, despite the recommendation PUE to the use of copper wiring in residential buildings. The use of aluminum is again permitted according to the order of the Ministry of Energy No. 968 of 10/16/2017. An aluminum cable means not what was laid in apartments since the 60s, but cables in which the cores are made of alloy, aluminum (up to 99%) with iron (up to 0.5%), which you can see in the table below.

Alloys 8176 and 8030, which were developed by RUSAL specialists, are suitable for these requirements. From March 20, 2019, amendments to the set of rules “Electrical installations of residential and public buildings. Design and installation rules ”that allow them to be used.

All this suggests that the aluminum wiring will return to home.

Basic requirements for operation

If you still decide to use aluminum wiring in an apartment or a private house, consider the following requirements:

- A cross section of at least 16 square meters. mm (we have already talked about this, but it will not be superfluous to recall).

- Use clamping contacts (as well as special grease that will prevent oxidation of the contacts and maintain a low level of transient resistance).

- Use welding of aluminum wires in junction boxes (large expenditures of time and finance are necessary, therefore they are rarely used). If you do not do the work yourself, follow the work of electricians in your home and monitor the process to adhere to all technical points.

It will also be useful for you to know the maximum load on aluminum wires of different sections. All data we provided in the table:

And remember, regardless of the type of wiring in your home, adhere to the rules of fire and electrical safety, as well as the rules of operation. So you can protect your family and your home from unwanted consequences and accidents. In the end, we recommend watching another useful video on the topic:

That's all I wanted to tell you about the pros, cons and dangers of using aluminum wiring. We hope you have weighed the pros and cons, and then made the right choice in favor of security.

We also recommend that you read:

Yes, a good useful article, especially for dummies of electricians and people far from wiring and electricity.

Thank you for the article! Useful and accessible written

Nowadays, aluminum cable is no longer relevant. The brittleness and brittleness of aluminum, as well as its conductivity, which is 1.6 times less than that of copper, made it fade into the background.

Aluminum cables are used in the electrical installation of power lines, with a cross section of 120 mm or more, due to its cheapness compared to copper cables with the same power.

Cable over 16 sq / mm is better to conduct aluminum, and inside the apartment 10 sq / mm or less, copper.