How to connect an aluminum wire with a copper wire - an overview of ways

What problems can arise when combining aluminum and copper

Not so long ago electrical wiring in the apartment or a private house was made of aluminum wire, as it was enough to provide power to all the existing few electrical appliances. With the development of the world of electronics and household appliances, there has been a tendency to increase the load on electrical circuits. Accordingly, there was a need to connect the old and new wiring.

When aluminum and copper are touched, a chemical reaction occurs, which subsequently worsens the electrical contact, the connection point begins to heat up and may eventually become cause fire and even fire. With increased ambient humidity, this process occurs quite quickly, since a thin film with high resistance is formed between the conductors, resulting in heating and an open circuit. But still, every electrician knows how to connect an aluminum wire with a copper one, in order to avoid an unpleasant situation in the future.

The video below illustrates the effects of unsafe contact between copper and aluminum:

In any case, it is recommended to replace the old wiring with copper, which will have a load capacity corresponding to the current consumption of electrical appliances. If it is not possible to completely replace the wiring with a new one, then partial wiring replacement. In this case, it becomes necessary to connect the old and new electrical wiring - copper and aluminum wires.

Methods for connecting different wires

There are several basic commonly accepted devices that make it possible to eliminate the direct contact between two materials acting aggressively on each other. Let's consider each separately.

Terminal blocks

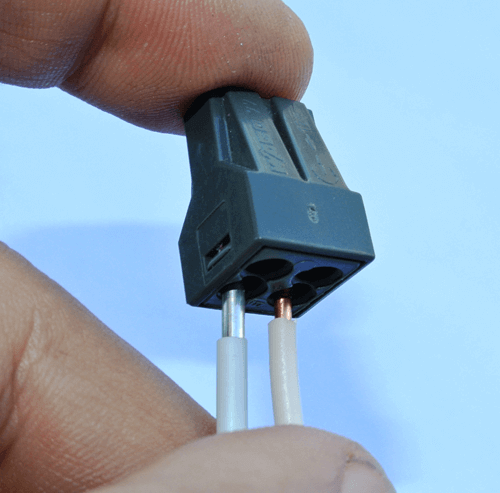

Terminal blocks can be equipped with a bolt or clamping mechanism.This design provides a connection to one terminal of aluminum, and to another copper conductive material, which are in contact with each other through a steel plate. The plate is made of neutral metal, which does not react with copper and aluminum - usually brass plates or tinned copper plates. For example, with the widely used Wago 2273 terminal, from two to eight conductors of different cross-sections can be connected simultaneously, fasten on DIN rail using a special mounting adapter.

The bolt clamp in the pads is more reliable and is used in power not high-voltage circuits. Most often it is carried out usingwalnut". This is a small junction box made of a dielectric material in the shape of a walnut, inside which there is a block of metal plates through which the contact between aluminum and copper wires occurs. All of the above methods relate to detachable connections, that is, for multiple connections and disconnections, if necessary.

An example illustrates the completed fastening of copper and aluminum in a junction box through the use of brass terminal blocks:

About, how to connect wires with WAGO terminalsread in our separate publication!

Crimping method

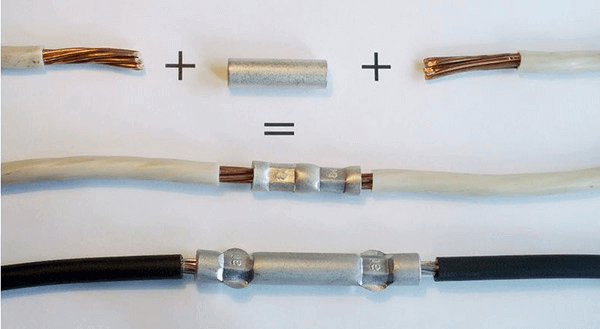

Sometimes, when laying and installing electrical wiring, it becomes necessary to perform high-quality one-piece connection of copper and aluminum wires by crimping using sleeves. More often it occurs at the entrance to an electrical cabinet, switchgear or when connecting a cable to an already installed unit, where it is impossible to replace aluminum with copper, and vice versa.

This type of connection of conductors is more expensive, as it requires a special tool. But at the same time, when conducting numerous installation works of such a plan, professionals often choose it.

Crimping wires with sleeves provides more reliable and durable contact. Using this method, copper and aluminum conductors are fastened even to particularly powerful and high-voltage consumers in production. To perform these works, you need a special tool and special copper-aluminum sleeves. Their compression can even be carried out using a conventional hammer and metal plates, which is not entirely correct, or there is a professional manual hydraulic press.

It is recommended to use such a compression not only when crimping sleeves, but also tips. By the way, they can also be made half of copper and aluminum, for connecting, for example, an aluminum cable to any device with copper terminals or terminals.

Typically, aluminum-copper sleeves are used to connect large strands of cable conductors. With small sections, for example, in home wiring, several conductors are crimped with one sleeve. At the same time, the wires are brought in from different sides, for connection as if in a joint, as shown in the photo above. Do not stack aluminum and copper conductors parallel to each other (lap), as shown in the illustration with a hydraulic press, because in this case there is a direct contact of aluminum and copper. Also, you can not use copper tinned sleeves with an aluminum cable.

Bolted connection

Very often, when working with electrical wiring, a simple person who is not involved in electrical work at home may have an urgent need to create a good and reliable contact between the aluminum and copper wires. Running to the store to buy special tools and materials is not advisable when doing one-time work, but they need to be done with high quality.

Then it makes sense to use an ordinary bolt with a nut and several washers. The main thing in this method is to separate two metals that are aggressive towards each other with washers, as shown in the figure below.

Bolted connection of aluminum and copper wire can be performed in a junction box, which is an integral part of any wiring in the house and in the apartment. Thus, even with different cross-section conductors are easily and qualitatively connected through a bolt.

The rings from the wire should be wrapped in the direction of tightening the nut, with a bolted connection. This is necessary so that when tightening the rings do not unwind and do not increase in diameter, but rather tightly wrap around the bolt.

The video clearly shows how to connect the wires of different materials with a bolt:

A similar method is the use of rivet. The following illustrates how to connect the wires with a rivet:

There is another option for the use of aluminum-copper tips and aluminum-copper washers. Can crimp aluminum cable lug and connect to the copper bus. Or, when using an aluminum-copper washer, you can crimp the aluminum cable with a conventional aluminum cable lug and connect it to the bus through this washer.

Features of the connection lived on the street

When installing a cable line in the street, all the connection elements are exposed to external negative factors, such as snow, icing, rain, etc. Therefore, to perform such work, only a hermetically sealed construction is required that is resistant to ultraviolet rays and low temperatures. When making connections on a pillar, roof and in another open place, they are most often used piercing clamps. You might be interested to know in more detail how to connect SIP with a copper cable on the street, as in this case, the connection of aluminum and copper in the open air occurs.

In rooms, when laying the cable in the wall under the plaster, the cable is laid intact in the strobe, and any connection even of uniform metals is undesirable. All connections in the socket or junction box are made in any of the ways described above, suitable for each individual situation.

Common mistakes, tips and tricks

To your attention a few useful tips that allow you to safely connect an aluminum wire with a copper wire between each other:

- Before connecting the wires with soldering, you need to know that copper tin It will be very simple, and aluminum only using special solder.

- It is impossible to compress the joints of both multicore and single-core conductors too much. Otherwise, deformation and damage to the cores will occur.

- It is always worth observing the marking and choosing the correct terminal blocks depending on the cross-section of the core and the type of installation (indoors or outdoors).

- In no case do not use ordinary twists to connect aluminum and copper wiring. This is one of the most unsafe ways of switching wires, which most often leads to a fire.

That is all we wanted to tell you about how to connect copper and aluminum wires. We hope that the provided methods and rules have helped you understand the essence of the work!

It will be useful to read:

The 7th edition of the PUE explicitly prohibits the use of aluminum in internal wiring if the cross-section of the current-carrying part is less than 15 square mm. This is explained by the formation of an oxide film on aluminum, which, strictly speaking, is not conductive. For a wire or bus with a cross section of less than 15 square mm, this film significantly reduces the cross section of the conductive part. On my own I will add that during short-circuit aluminum burns no worse than a sparkler - with splashes.

Why is it that they produce aluminum wires and cables, as well as tires and lugs, all this is present in the structures that I built and built before me, and still stand. In 5-floors, ALUMINUM is still worth it. and where in the PUE it is forbidden ....?

Because the connection of individual electrical appliances, for example, equipment such as pumps, can be carried out with aluminum wires, as well as when connecting a powerful load, where a cross section of more than 16 square meters is needed. mm use aluminum for economic reasons.

In relation to the existing electrical installations, the PUE is advisory in nature, only when reconstructing the existing electrical installation or when building a new PUE, it is mandatory for execution.

If you are doing repairs and there is an opportunity, then it is better of course to change the wiring in the apartment to copper, if it is not possible, then distribute the load reasonably across different outlets.

Clause 7.1.34. - as far as I understand

Roman, PUE - this is certainly wonderful, but only 80% of all apartments and houses in the country have aluminum wiring, which we inherited from the USSR. And what, someone with one stroke of the pen, it turns out, banned the use of electricity in 80% of the country's households? Indeed, together with the ban, the replacement of aluminum wiring at the expense of the one who banned it is not legally prescribed anywhere. Not for nothing now they are returning to the resolution of aluminum. After all, to ban something - did not work ....

All the same, replacing aluminum with copper, even in a small Brezhnev treshka, is an enormous expense (both financial and temporary) for an average-static family, with average national salaries of 17-18 thousand.

Now Deripaska is organizing everything in the new houses and will overhaul the electrical wiring in the old aluminum, and after a couple of decades it’s not that the enormous expenses for replacing aluminum with copper with average wages in the country of 17-18 thousand will have to be paid, but also a complete repair in the apartment, and the neighbors too.

There is not "bare" aluminum, but an alloy with steel. Just two types of wire. They already wrote about it ...

Roman, so now it seems like if people do repairs, they all change the wiring to copper.

To me the installer of suspended ceilings, when I hung the lamp I wanted to connect it with aluminum wiring by twisting (the lamp is copper), I saw it well.

It seems to me that such problems can occur with large current loads of 2A and higher. I am not an installer doing repairs on my own. To connect copper and aluminum wires, I used twisting + soldering and from the top I put on a regular screw terminal. All this design has been working for 8 years and I have not experienced any problems with it!

Michael, please describe your soldering technology. I would like to take note.

flux f-64 try

Replacing the wiring is necessary for two reasons: 1) the power of a modern kettle is 2.2 and sometimes 3.3 kW with a Sovdepi of 300-1000 watts, about the same thing with an iron, an electric heater, electric boilers and instantaneous water heaters with a scoop almost never happened, the same for microwave ovens, toasters, deep fryers and even a laser printer are about 0.5 kW, a vacuum cleaner 1.2 kW, not to mention the rarely used rotary hammers, grinders, and in addition, the starting currents of the refrigerator, one or two freezers, and this can work in many cases 2 ) so-called wires "noodles" had only one layer of insulation and often parted in half under the parquet, to the chandelier - on the floor of neighbors from above, at best, under the screed and pipe breakthrough and flooding very often led to electrocorrosive destruction of the wire strands, on the solvremennyh wires of ball screw or PVA 2 layers of PVC insulation and the destruction due to electrolysis, the probability is much lower. And from my own experience I can say that the only socket with a ground in the kitchen successfully failed after the neighbors leaked from above: of the three wires in total isolation, and there it was - the zero-earth-phase only survived, and the ground and phase " ate each other. Leaving in the summer for a week on vacation, etc. you will not turn off the refrigerator, the freezer automatically on the shield. So even for chandeliers, it makes sense to think about replacing the wiring during the first repair of the apartment, otherwise you would not have to make another repair after the repair due to wiring malfunctions

The author categorically states that copper should not come into contact with aluminum under any conditions! But at the same time, he is not at all confused by the use of alumino-copper sleeves and tips, where copper and aluminum are called “fused together” ... ..