What are cable glands?

Classification

For better clarity, the varieties of cable sleeves are presented in the block diagram:

Let us consider in more detail each classification.

Appointment

So, we will consider what types and types of cable sleeves are divided into and immediately tell you about the scope of each variety.

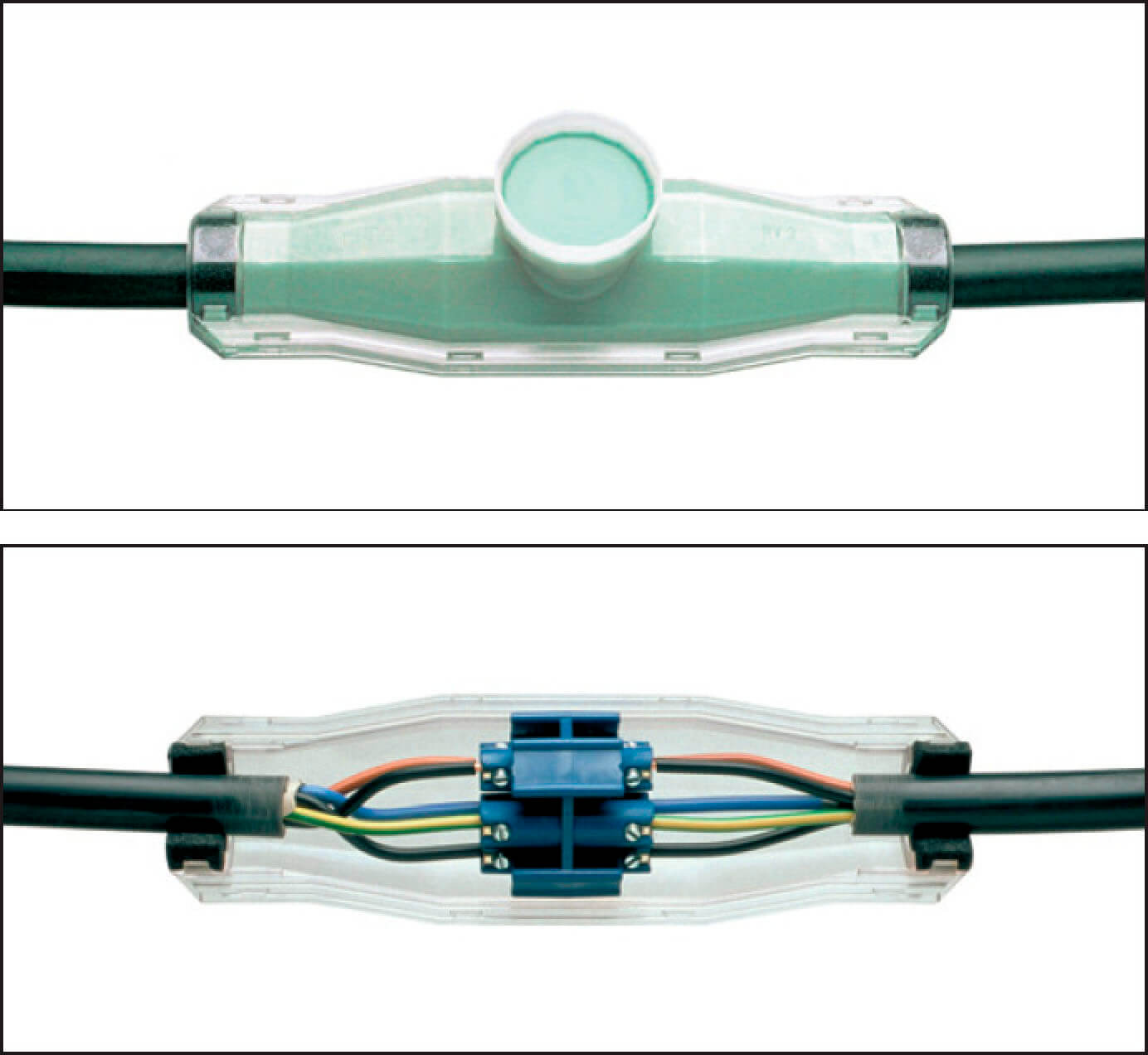

Connecting. Perhaps this is one of the most popular connecting elements. Connection of the cable of electric lines is more often than other types of installation. A mandatory requirement for such connection elements is reliable tightness. Depending on the requirements, they can be collapsible and not collapsible. For their manufacture, a material is selected that is resistant to damage from the external environment.

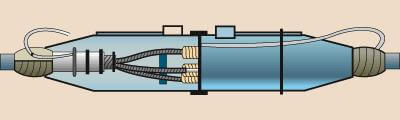

Lead couplings are used for conductor connections in which the sheath is made of lead or aluminum. They are made of pipes, as can be seen in the photo below. Lead cable sleeves are quite heavy.

Epoxy. They are used to connect cable laid in trenches, tunnels, mines. These products are made of epoxy resin. As a rule, they are protected with an asbestos or metal casing. After installation, the cavity is filled with epoxy.

Another view heat shrinkable coupling. This is the most common way to isolate compounds due to simple technology. They are easy to install at the junction. Then, acting on them with hot air, for example, from a gas burner or electric hairdryer, they are cased until an airtight coating is formed. Their use in compounds allows to increase the strength of the product and increase the duration of operation. Shrinkage reduces the risk of breakdown due to its high dialectic characteristics. The flexibility of the material significantly facilitates ease of installation. The shrinkage range allows the use of these products at the junction of cable lines of various diameters.

Also usetransitional couplings, the purpose of which is to provide sealing of different cables. It is worth noting that if only the transition diameters are different, then it is more advisable to use heat-shrink types of connectors.

Often there is a need for cutting and branching cable lines. In this case, are used branch connectors. For their manufacture, various types of materials are used. For example, polyethylene, designed for communication lines.Varieties of these products make it possible to satisfy a wide range of branches used in communication lines.

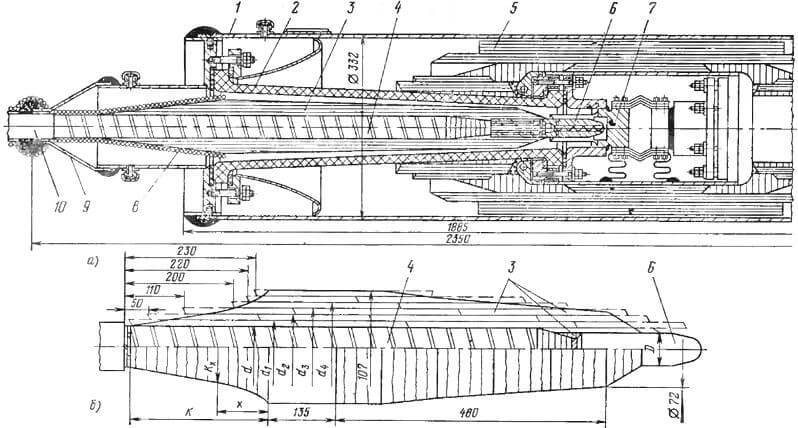

Locking. This type of connector is used in high voltage power grids of about 110 kV. They have a fairly complex device. Consider this using the example of a cable joint with an oil filler - МСТМ-110 (to enlarge, click on the picture).

Where:

- 1 - housing;

- 2 - insulator;

- 3 - edge isolation;

- 4 - insulation of the cable itself;

- 5 - isolation of the central part;

- 6 - tip;

- 7 - contact socket;

- 8 - a protective screen;

- 9 - bell;

- 10 - shell.

They are used in cases of hydrostatic pressure exceeding the norm. This happens when there is a big level difference with a long track length. We can say that such a connection includes a variety of terminal and coupling types. MCTM is a connection of two end couplings. Two porcelain insulators and a body of non-magnetic cylindrical material create 3 chambers. A copper spring connects the caps of the insulators. Above they are closed by a cylindrical screen. The insulation screen is covered with impregnated paper. The chambers are evacuated before filling with oil and then filled.

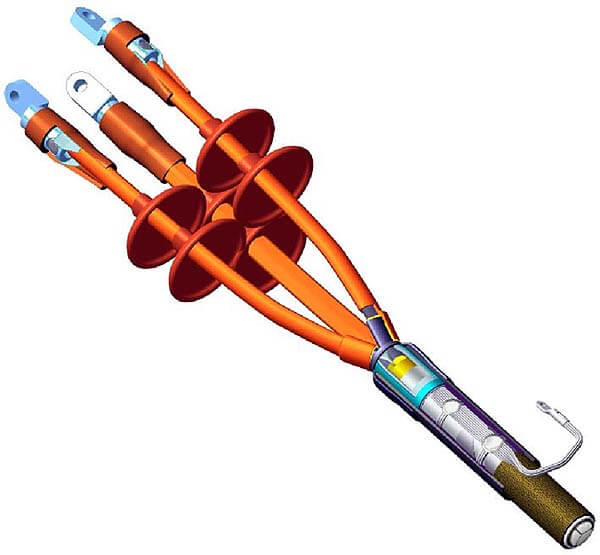

End sleeves are used respectively for cable termination. In essence, this is a common cap in the form of a cap. As an example of such an insulator, we can consider the building insulator SIP. Like isolation twisting wires apartment wiring they are used for communication lines and power networks. Or they are also used for cutting multicore cables. Like for example in this picture:

This is the most common way to insulate a three-wire conductor using a cable termination. By design, they are divided into single-phase and three-phase connectors. For example, single-phase KNO-20 is used to insulate the end of a cable with a voltage of 20-25 kV, having paper insulation with a metal sheath for each core.

Multiphase insulated connectors are used for multi-core cable.

Selection recommendations

During installation or repair work, the connection or termination of the cable should preserve its mechanical and technical characteristics. It is important to remember compliance with fire safety and technical supervision. For connection it is necessary to choose products of the corresponding section. The material from which they are made must comply with the requirements laid down in the project or other guidance documents.

This article examined what types and types of cable sleeves are. Having studied the variety and purpose of these products, you can make the right choice of connection method during installation work and in other cases, which are the case with the operation of communication lines and electrical networks.

Useful on the topic: