What are the required dielectric gloves for and how are they tested?

Dielectric gloves are a hand protection against electric shock. The main purpose and objective is to protect the skin of human hands (fingers, palms) from touching devices and parts that are under electrical voltage. Insulating gloves are the main thing electrical protective device in an electrical installation up to 1000 V. In electrical installations with voltages above 1000 V, this is an additional insulating protective measure against electric shock. In this article, we will consider the purpose, rules of use and methodology for testing dielectric gloves.

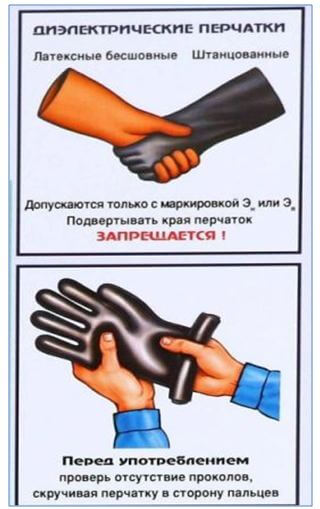

Types of gloves

Varieties of such workwear are negligible. Gloves are made, as a rule, from sheet rubber (rubber) or latex and have one standard size. The width of such overalls should be chosen so that warm mittens can be worn under them (this is if the work is carried out in cold and frosty weather). If the street temperature is negative, then under the insulating gloves should wear knitted leggings. This will protect your hands from hypothermia and frostbite.

Protective equipment is divided into several types:

- two-fingered and five-fingered;

- Seamless and with a seam.

Important! In electrical installations, the use of insulating gloves is permitted, which are marked “Ev” and “En”.

The designation "Ev" means that the material is able to protect human skin from electricity with voltages above 1000 V (of course, as an additional method of protection), and the designation "En", respectively, is considered the main protective coating against electric currents up to 1000 V. This is in accordance with GOST 12.4 .103-83.

Test of strength

Testing insulating gloves is a necessary measure during their operation. A similar check (verification period) is carried out once every six months (the frequency of the check depends on the marking “Ev” and “En”).

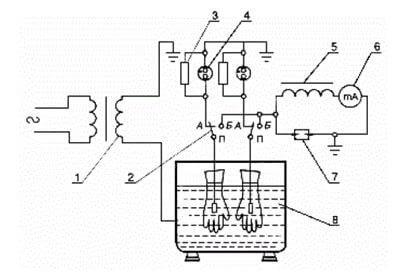

The scheme for checking mittens, bot and galoshes for strength:

- 1 - test transformer;

- 2 - switching contacts;

- 3 - shunt resistance;

- 4 - gas discharge lamp;

- 5 – throttle;

- 6 - ammeter (mA);

- 7 - arrester;

- 8 - a container of water.

Before starting the test, it is necessary to set the switch from the corresponding contacts to position A. This is necessary in order to establish the absence (presence) of breakdown with the help of signal lamps. If there is no breakdown, then the switch is moved to position B and the electric current that passes through the gloves is measured. If the passing current exceeds the norm, then such gloves go into marriage. Those mittens that are rejected are strictly prohibited to use in work! Since they are unable to protect a person from electric shock. When the test is over, the gaiters are dried.

The verification scheme may be slightly modified, but the essence remains the same.Now we will consider another test procedure, where we will tell you how to use the installation for checking gloves.

So, the dielectric material of the mitt can be checked by an example: water is poured into the container of the tested device and into the sample (gloves). Its temperature ranges from 10 to 40 degrees Celsius. The distance from the edge of the glove to the water should not exceed 55 millimeters. The edges of the gaiters and containers must remain dry.

The voltage that enters the container body and the electrode that sinks inside the glove has its own requirements and is equal to 6 kV. The test lasts one minute. The milliammeter should show the current value that passes through the gaiters - 6 mA.

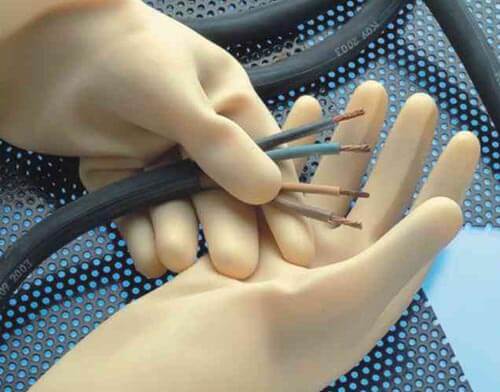

The dielectric material of which the gloves are made should dry after testing. To do this, they are placed in a special tank, such as shown in the photo below:

After drying, insulate gloves with a test stamp on which the date of use of protective cuffs (the date by which the material is suitable) should be written. For instance:

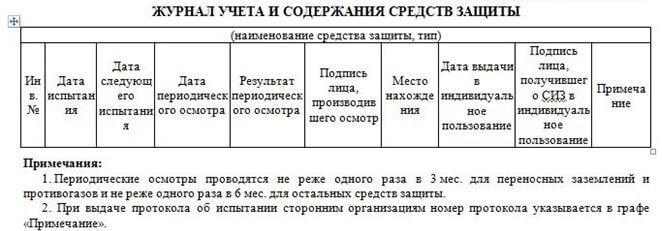

The stamp should be clearly visible, it must be applied with indelible paint. Then you need to enter information in the journal, which indicates the test of protective equipment. The log is as follows:

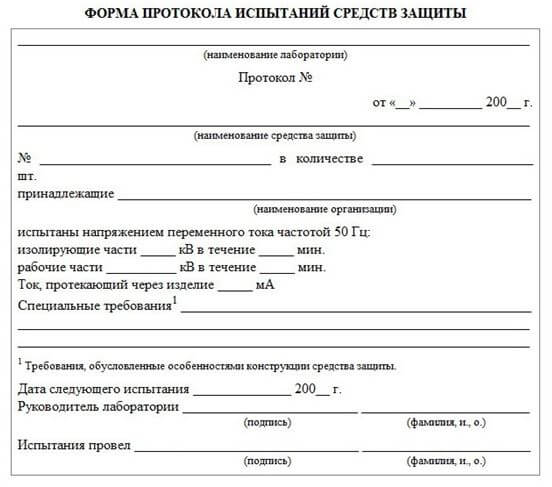

After completing all the above procedures, if there is such a need, a protocol is issued that indicates the verification of electrical insulating cuffs. A sample protocol is as follows:

We also recommend watching a video that demonstrates the technology of testing dielectric gloves:

Terms of use

The dielectric material from which the protective gloves are made has its own service life. Therefore, before putting them into use, you must first check them. What is dielectric material tested for? Particular care should be taken to such moments:

- the presence of a verification stamp;

- absence or presence of mechanical damage;

- lack of pollution and moisture;

- cracks and other damage.

How to check products for cracks and punctures? This is done very simply: you just need to twist the gloves from the edges to the fingers. Thus, it will be seen that the dielectric material crag has a marriage. The image below demonstrates the verification methodology:

How to protect the dielectric material of which the protective gaiters are made from various mechanical damage? For protection, wearing gloves made of leather or tarpaulin is allowed on top.

At the time of work CATEGORALLY FORBIDDEN to wrap the edges of the gloves. After each work, you need to wash them using a solution (based on soda or soap). Then they need to be thoroughly dried.

Instructions for use of cuffs, which include dielectric material, are standard and are described at each production site before starting electrical work. Since the purpose of electrical insulating gloves is protection against electric shock, do not neglect them and use the products in accordance with the instructions and special operating rules.

So we examined how dielectric gloves are tested and what are the rules for using these electrical protective equipment. We hope the information was useful and interesting!

Surely you do not know: