Why connect the machines through the comb and how to do it right?

Design Features

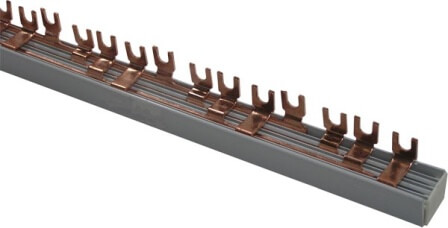

To begin, consider the design of the comb. The product consists of a copper plate placed in a plastic insulation that does not support combustion. From this plate, special inlets leave, thanks to which the connection of machines in the shield. The number of plates corresponds to the number of poles.

Please note that there are combs with a pitch of 18 and 27 mm. The first are intended for switching AB, with a width equal to one module. Accordingly, 27 mm is a width of 1.5 modules. Pay attention to this moment when choosing a distribution bus for your own conditions!

By the number of poles, the connecting busbars are divided into single-pole, two-pole, three-pole and four-pole. Each embodiment has its own purpose. For example, a single-pole comb uses to connect a single-phase circuit breaker, and a four-pole comb, respectively, for mounting three-phase RCDs to 4 poles (three phases and zero).

The number of taps can be from 12 to 60, so the use of combs to connect two electric machines is not a rational solution. It is advisable to use a distribution bus when assembling large shields.

The taps themselves can be pin (marking pin) or fork (fork). The former are used much more often, because fork bends are not suitable for all machines, they need a special clamp.

The last design feature that I would like to talk about is the cross section of the bends. As a rule, bends produce a cross section of 16 mm.sq., which is quite enough to withstand a current load of 63 A.

Advantages and disadvantages

First, let's talk about the advantages of the busbar for circuit breakers. So, comb has the following advantages when electrical wiring:

- Better connection of switching equipment. If the jumper connection is represented by two ends of the wire in one clamp, then the use of a comb bus reduces this value by 2 times, which is positively displayed on the quality of the contact.

- As we have already said, the connecting comb of the milking machine can withstand up to 63 A.Make a loop of wire, cross-section 16 mm.kv. will be much harder.

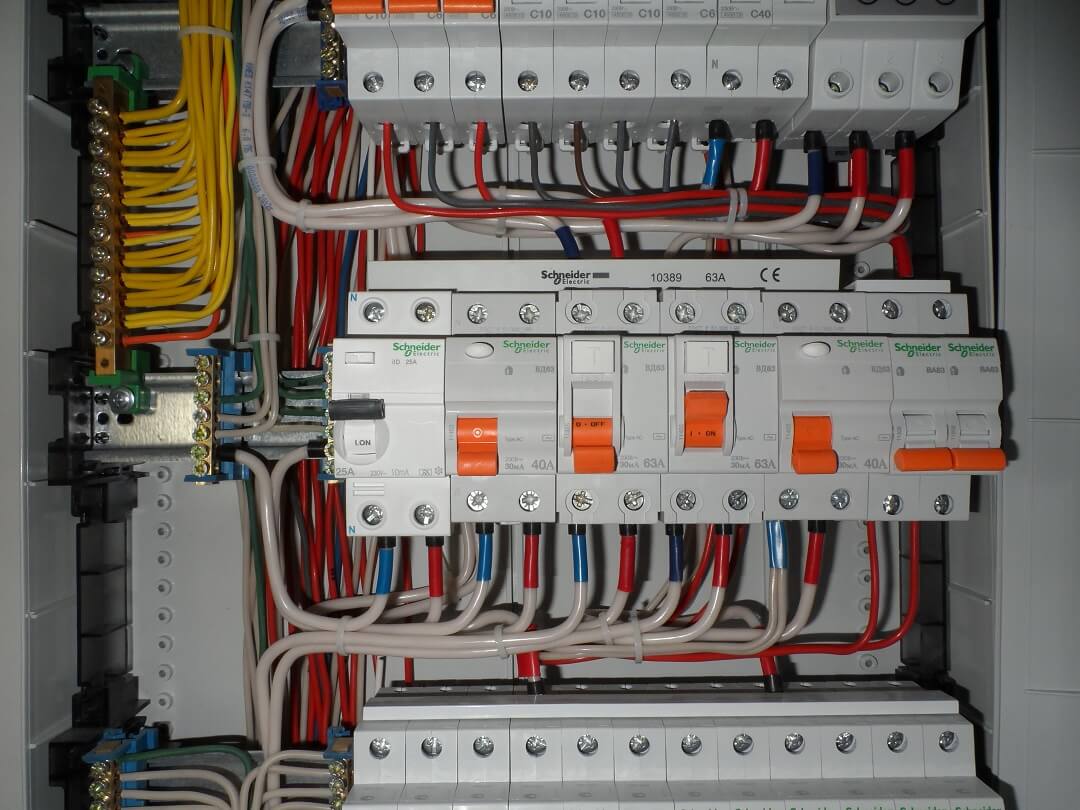

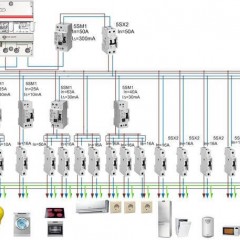

- The wiring in the shield using the distribution bus looks more accurate, as can be seen in the photo below:

As for the disadvantages, they are as follows:

- It is not always possible to connect machines from different manufacturers. The fact is that various companies can produce modular switching products of different heights. As a result, the tap does not always reach the smaller AV connector.

- More problematic replacement of circuit breakers in the panel. To replace one device, you will have to loosen the connecting bus on all the connectors, otherwise you won’t be able to raise it higher, and you won’t be able to get the machine without it.

- If there is a need to add another AB to the shield, you will either have to change the comb completely, or connect it with a jumper, which will negatively affect the aesthetic appearance of the switchboard. In addition, when replacing, it will be necessary to disconnect the voltage on all supply lines, which is sometimes very undesirable, especially in production.

By the way, the comb busbar can be used to connect not only circuit breakers, but also RCDs, as well as difavtomatov. About how to connect this connector in the shield, we will describe further.

Installation and Connection Rules

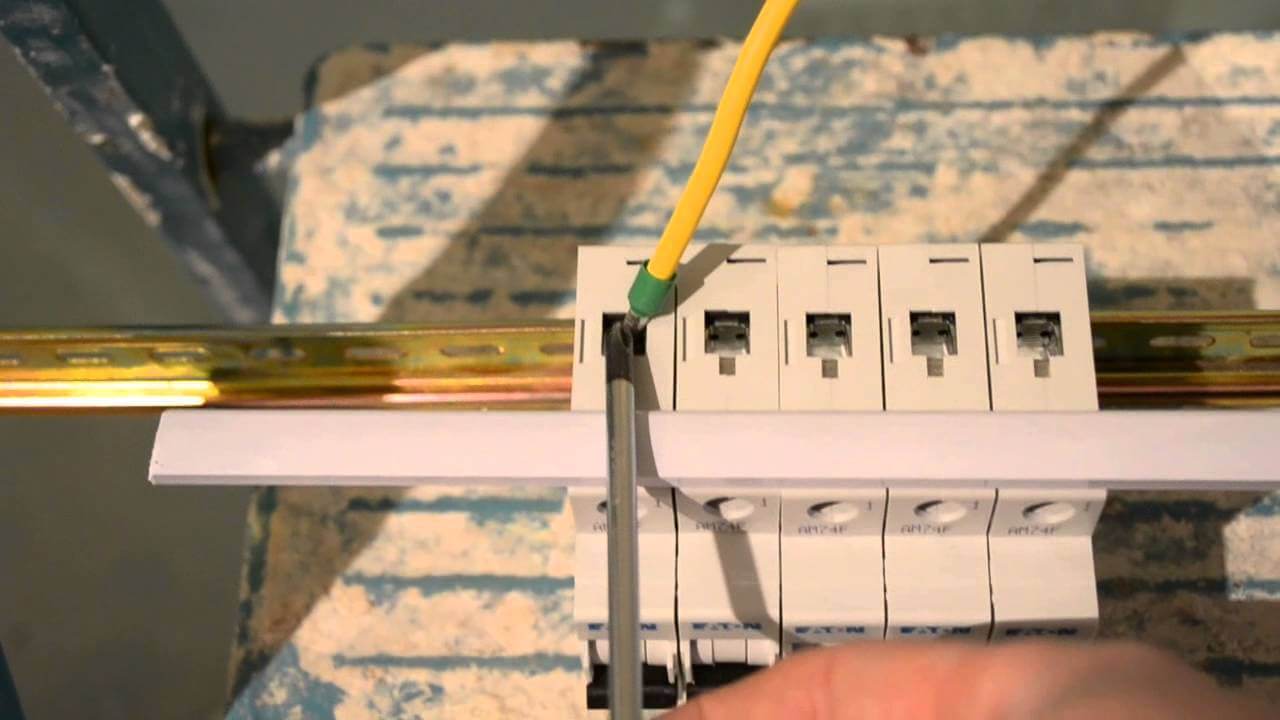

First you need to measure the desired length of the comb (if the remainder is anyway) and cut off the piece that you need. Cutting a tire for machines is best with a hacksaw. We recommend that you cut off the dielectric plastic housing with a margin of 1-2 cm, which will protect live parts and prevent short circuit. At the edges, it is also necessary to put plugs or insulate the ends with ordinary electrical tape.

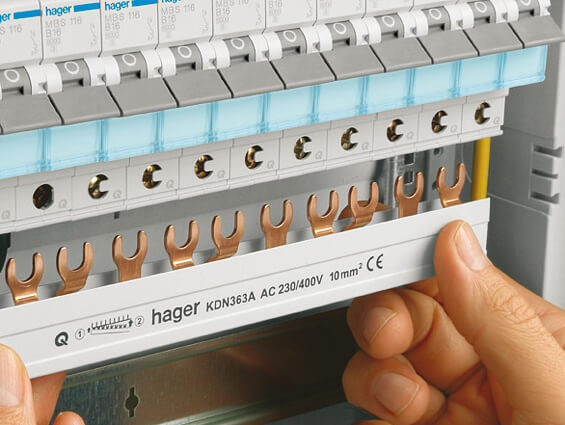

After a suitable length is cut off, we proceed to connect the circuit breakers with a comb. Everything is simple here, the bus must be placed at the top, insert the pin bends into the corresponding connectors and tighten the screws. In one of the terminals, the extreme, you need to connect the input supply wire.

The connection process is described in detail in the video example:

If you use a connecting comb with male bends, some machine manufacturers (Hager, ABB) provides a separate connector (located at the bottom), to which you need to install. This moment is clearly demonstrated in the video:

As you can see, there is nothing complicated in installing and connecting a single-row connection bus, at least for the example of connecting single-pole AVs. As for the RCD, difavtomatov and bipolar switches, their connection will look a little different.

In this case, you need to use a bipolar comb. The phase and zero taps of such buses are located through one, so you need to make a connection in accordance with the marking (each branch in its own connector), and then tighten the screw clamps securely.

That's all we wanted to tell you about connecting the connecting bus for machines. Do it yourself even an inexperienced electrician can do the installation. The main thing is to take into account the recommendations provided!

We also recommend reading: