Choosing a soldering iron for soldering wires - what should I look for?

Key selection criteria

So, first, briefly consider the most important parameters that you should pay attention to when buying a soldering iron.

Heater type

First of all, devices are divided into electric and gas. First, let's talk about those that run on gas.

A gas soldering iron is recommended for soldering wires in junction boxes. It is convenient in that it works offline, without electricity, which is important for electrical work. In addition, such a device can be used as a heat shrink dryer.

The disadvantages of gas devices include the difficulty of working with microcircuits, as well as the fact that when gas is burned, substances harmful to the body are released into the atmosphere, so working with such a device for a long time is extremely dangerous for health.

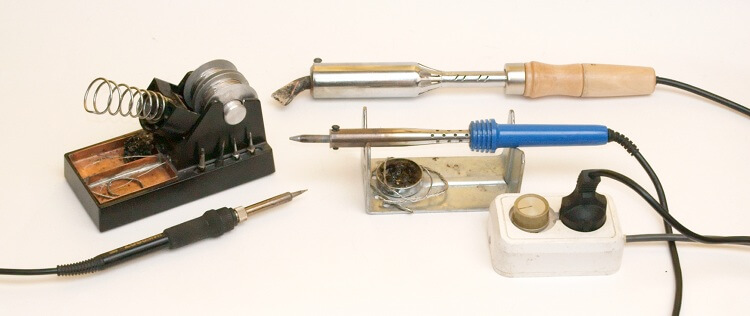

It is advisable to choose an electric soldering iron for soldering microcircuits and the same wires, if there are no problems with the power supply. Electric models are divided into the following types:

- Spiral. The cheapest, practical and durable type of heater. The disadvantage is that it heats up for a long time, but this is not so important if you need to choose a soldering iron for the house.

- Ceramic. More expensive and fragile at the same time (it may stop working even with a small blow). Advantage - heats up quickly. If the main thing for you is to choose a device so that it quickly and strongly heats up, a model with a ceramic heater will be the most optimal solution.

- Impulse. Another embodiment that can quickly heat up. It is better to choose a pulse soldering iron for soldering microcircuits and for working with printed circuit boards. Such a tool will cost more and is used to a greater extent only for the listed works.

Separately, mention should be made of such an embodiment as a soldering station. With its help, it is possible to solder wires and microcircuits faster and better. For ham radio soldering station selection will be the best solution!

Power

As for the choice of power of an electric soldering iron, the following recommendations should be taken into account:

- power up to 10 W can be used for soldering simple microcircuits;

- from 20 to 40 watts - this is the optimal power for domestic use;

- choosing a model for 60-100 watts is advisable if you are going to solder the wires;

- over 100 watts home masters should not use, becausesuch devices have their own specific scope of application (soldering radiators, metal parts, etc.).

Additional features

Also, when choosing a soldering iron, you should pay attention to such moments as:

- The handle should be well protected from overheating. In this case, the wooden handle has the best performance. Plastic handles heat up faster, which interferes with smooth operation, and hard rubber ones are heavier than analogs, which also reduces usability, especially when soldering microcircuits.

- The sting should be copper, it is easier to process and also easier to clean from carbon deposits. It is advisable that the kit comes with a set of tips, different in shape. It is also good if it is possible to replace the sting or to adjust its length. It is believed that the direct sting is the most convenient for work, especially for beginners.

- The power cord must be flexible, long and always double insulated.

- The plug for connecting to the network is better when collapsible. It seems to be a trifle, but still testifies to the quality of the device and at the same time simplifies its repair.

- Pay attention to the equipment. As a rule, high-quality soldering irons are equipped with a case, a stand for a tip, a sponge for cleaning the tip, etc.

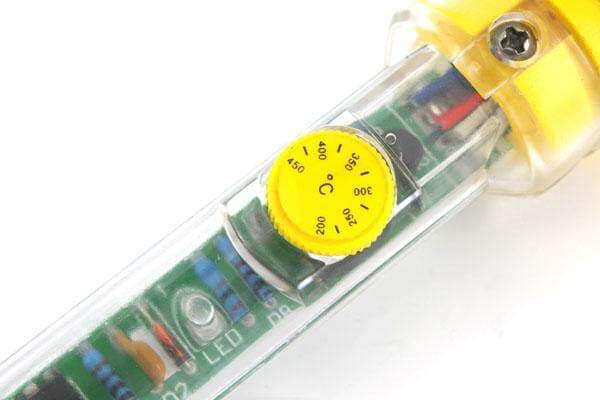

- We recommend choosing a soldering iron with a temperature regulator, which will allow you to adjust the temperature of the tip heating for your own application conditions.

- The function of constant temperature support protects the device from burnout.

This is all the advice we wanted to provide you. As you can see, there are many nuances that you need to pay attention to when choosing a soldering iron for the home.

To summarize

So, you have studied the main criteria by which a tool is selected for soldering wires and microcircuits. Now let us briefly summarize again to consolidate what we have learned:

- For printed circuit boards and microcircuits, it is better to choose a pulsed soldering iron or spiral, but with a power of no more than 30 watts.

- To connect the wires and other electrical work, a gas model or an electric model with a power of 60 to 100 watts is suitable.

- To solder metal parts you need a powerful device (from 100 W or more).

We also recommend watching a useful video on the topic:

So we figured out how to choose a soldering iron for soldering wires and microcircuits. We hope that the provided instruction helped you in choosing the right tool for home use!

Surely you do not know:

How to choose a soldering iron for soldering circuits like TDA

It is better to use a pulse; it heats up faster but also costs more