Typical schemes and methods for starting synchronous motors

To ensure the operation of powerful electric drives are used synchronous electric motors. They have found application in compressor plants, pumps, systems, rolling mills, fans. They are used in metallurgy, cement, oil and gas and other industries where it is necessary to use high power equipment. In this article, we decided to tell the readers of the site Elecroexperthow synchronized motors can be started.

Advantages and disadvantages

Synchronous motors are structurally more complicated than asynchronous ones, but they have a number of advantages:

- The operation of synchronous electric motors to a lesser extent depends on fluctuations in the voltage of the supply network.

- Compared to asynchronous ones, they have greater efficiency and better mechanical characteristics with smaller dimensions.

- The rotation speed is independent of the load. That is, load fluctuations in the operating range do not affect the speed.

- They can work with significant overloads on the shaft. If short-term peak overloads occur, an increase in current in the field winding compensates for these overloads.

- With an optimally selected mode of excitation current, electric motors do not consume and do not transfer reactive energy to the network, i.e. cosϕ is equal to one. Engines, working with overexcitation, are capable of generating reactive energy. What allows them to be used not only as engines, but also as compensators. If reactive energy is needed, an increased voltage is applied to the field coil.

With all the positive qualities of synchronous electric motors, they have a significant drawback - the complexity of starting up. They do not have a starting torque. To start, special equipment is required. This has long limited the use of such engines.

Startup Methods

Synchronous electric motors can be started in three ways - using an additional motor, asynchronous and frequency starting. When choosing a method, the design of the rotor is taken into account.

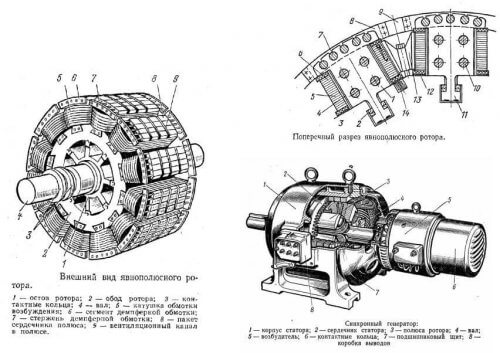

It is performed with permanent magnets, with electromagnetic excitation or combined. Along with the field winding, a short-circuited winding, a squirrel cage, is mounted on the rotor. It is also called damping winding.

Starting with a booster engine

This starting method is rarely used in practice, because it is difficult to technically implement. An additional electric motor is required, which is mechanically connected to the rotor of the synchronous motor.

With the help of an accelerating motor, the rotor is untwisted to values close to the speed of rotation of the stator field (to synchronous speed). Then a constant voltage is applied to the field winding of the rotor.

The control is carried out by light bulbs that are connected parallel to the circuit breaker, which supplies voltage to the stator windings. The circuit breaker must be turned off.

At the initial moment, the lamps flash, but when they reach the rated speed, they stop burning. At this point, voltage is applied to the stator windings. Then the synchronous electric motor can work independently.

Then the additional motor is disconnected from the network, and in some cases it is disconnected mechanically. These are the features of starting with an accelerating motor.

Asynchronous start

The asynchronous start method is by far the most common. Such a start was made possible after the rotor design was changed. Its advantage is that an additional accelerating motor is not needed, since in addition to the field winding, short-circuited squirrel cage rods were mounted in the rotor, which made it possible to start it in asynchronous mode. Under this condition, this method of start-up was widely used.

Immediately recommend watching a video on the topic:

When voltage is applied to the stator winding, the motor accelerates in asynchronous mode. After reaching revolutions close to nominal, the excitation winding is turned on.

The electric machine enters synchronism mode. But not so simple. During start-up, a voltage appears in the field winding, which increases with increasing speed. It creates a magnetic flux that affects the stator currents.

In this case, a braking torque occurs, which can stop the acceleration of the rotor. To reduce the harmful effects of the field winding, they are connected to a discharge or compensation resistor. In practice, these resistors They are large heavy boxes where steel spirals are used as a resistive element. If this is not done, then a breakdown of the insulation may occur due to increasing voltage. What will result in equipment failure.

After reaching the sub-synchronous speed, the resistors are disconnected from the excitation winding, and a constant voltage is supplied to it from the generator (in the generator-motor system) or from the thyristor exciter (such devices are called VTE, TVU and so on, depending on the series). As a result, the engine goes into synchronous mode.

The disadvantages of this method are large inrush currents, which causes a significant drawdown in the supply voltage. This can lead to the shutdown of other synchronous machines operating on this line, as a result of the operation of the low voltage protections. To reduce this effect, the stator winding circuits are connected to compensation devices that limit inrush currents.

It can be:

- Additional resistors or reactors that limit inrush currents. After acceleration, they are shunted, and mains voltage is applied to the stator windings.

- The use of autotransformers. With their help, the input voltage decreases. Upon reaching a rotation speed of 95-97% of the working, switching occurs. Autotransformers are turned off, and AC voltage is applied to the windings. As a result, the electric motor enters synchronization mode. This method is technically more complex and expensive. And autotransformers often fail. Therefore, in practice, this method is rarely used.

Frequency start

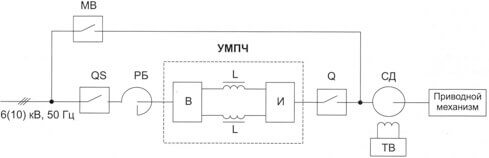

Frequency starting of synchronous motors is used to start high-power devices (from 1 to 10 MW) with an operating voltage of 6, 10 KV, both in the easy start mode (with the fan nature of the load) and with heavy start (ball mill drives). For these purposes, soft frequency start devices are available.

The principle of operation is similar to high-voltage and low-voltage devices operating according to the frequency converter circuit.They provide a starting torque of up to 100% of the nominal, and also provide the launch of several engines from one device. You see an example of a circuit with a soft starter below, it turns on for the time the engine starts, and then it is removed from the circuit, after which the engine is connected to the network directly.

Excitation systems

Until recently, an independent excitation generator was used for excitation. It was located on the same shaft with a synchronous electric motor. Such a scheme is still applied at some enterprises, but it is outdated and is now not applied. Now, to regulate the excitation, VTE thyristor pathogens are used.

They provide:

- optimal starting mode of the synchronous motor;

- maintaining a given field current within predetermined limits;

- automatic regulation of the excitation voltage depending on the load;

- limitation of the maximum and minimum excitation current;

- instantaneous increase in the excitation current while lowering the supply voltage;

- damping of the rotor field when disconnected from the supply network;

- insulation status monitoring with fault notification;

- provide a check of the state of the field winding when the motor is idle;

- work with a high-voltage frequency converter, providing asynchronous and synchronous start-up.

These devices are highly reliable. The main disadvantage is the high price.

In conclusion, we note that the most common way to start synchronous motors is asynchronous start. I practically did not find the application of starting using an additional electric motor. At the same time, a frequency start, which allows you to automatically solve the start problems, is quite expensive.

Related materials: