Home-made induction boiler - 2 design options

Induction water heaters are good because they consume the least amount of electricity compared to other types of electric boilers for heating. However, not everyone can afford such a pleasure, especially for use in summer cottages, which are rarely visited. This is due to the high price of products, which can vary from 25 to 100 thousand. In order to please yourself with such an electric heater and at the same time save your own money, we recommend making your own induction boiler. On how to assemble at home, read on!

Idea # 1 - A Simple Swirl Heater

First of all, familiarize yourself with how this heating option works and what are its advantages over alternative boiler options. The video provided below will give you all the answers!

From materials for making homemade products you will need:

- Plastic pipe with an inner diameter of not more than 50 mm.

- Steel wire with a diameter of not more than 7 mm.

- 2 adapters for connection to the heating system (pipes).

- Fine mesh mesh.

- Enamelled copper wire.

- High frequency inverter.

- Insulation material.

Having prepared all the materials, you can proceed to the assembly of the induction boiler with your own hands. First, cut the steel wire into 5-centimeter pieces. After that, close one of the sides of the plastic pipe with a mesh and pour the cut wire inside. The amount of material should be such that the amount of homemade was completely "clogged" with wire. Next, the second end is closed with a metal mesh, which will prevent the spread of wire through the heating system.

When the filling is prepared, it is necessary to independently make the connection points of the home-made vortex boiler to the heating main. To do this, the adapters are fixed on both sides of the pipe by welding or by a threaded connection.

Next, you need to make the heating element of the device yourself - an induction coil. All that is needed is to wind about 90-100 turns of copper wire over the pipe. Be sure to follow the step between the turns so that the home-made induction boiler works evenly. After full winding, the ends of the copper wire are connected to the inverter and, finally, the boiler body can be assembled and insulated with suitable heat and conductive material.

Starting a homemade heater must be done only after connecting to a coolant - water. If you turn on the inverter without water in the housing, the pipe will instantly melt and all your efforts will be in vain.

That's the whole instruction that allows you to make an induction boiler from improvised means at home.This homemade product can be installed on any part of the heating system, but because of the not very attractive appearance, we recommend hiding it away from the eyes.

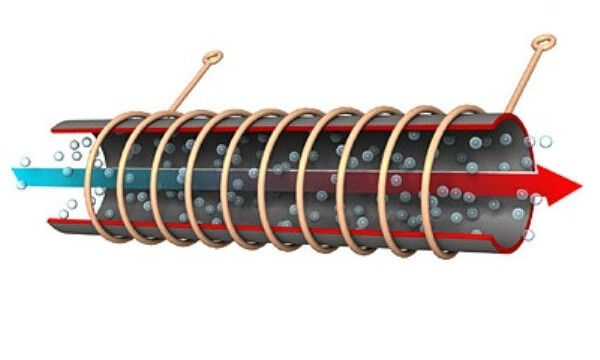

You can clearly see the principle of operation of the device in this photo:

As you can see, the core inside is red-hot, which is due to the influence of an electromagnetic field. We recommend viewing the tests of the assembled device in a video example:

Idea No. 2 - A more powerful device

To make a powerful induction boiler with your own hands, you just need to be able to use welding. In fact, the assembly technology is not too complicated and any self-taught electrician will be able to cope with it, as you will see after reading.

So, from the materials you will need:

- two pieces of metal pipe of various diameters;

- enameled copper wire;

- two adapters for heating pipes (for supply and return);

- heat insulating casing;

- three phase inverter.

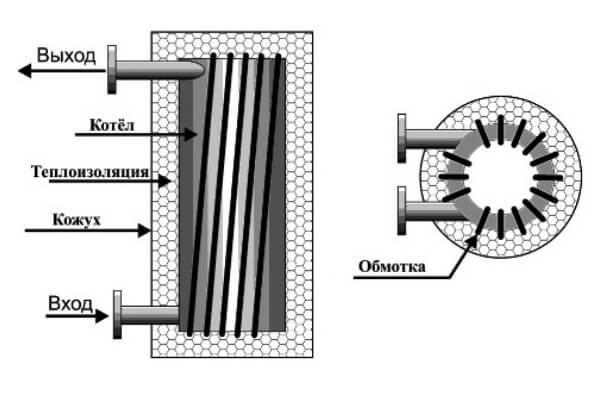

A drawing of a homemade heater is as follows:

As you can see, one pipe needs to be welded inside another to make a hollow tank in the form of a cylinder. Also, with the help of a welding machine, it is necessary to “embed” two nozzles into a container for supplying cold water and hot outlet to the heating system.

Further, as shown in the diagram above, it is necessary to wind a copper wire on the body of the induction boiler. Winding, as you know, will serve as a heating element and, in contact with the coolant, will heat it. On top of the created structure, it is necessary to pull the insulating cover, then open the water supply and test the system.

We also recommend that you watch a visual video instruction for assembling a similar device at home:

And finally, we advise you to familiarize yourself with the master class on the manufacture of induction boiler from tiles:

So we have provided 2 design options for a home-made induction boiler that heats the water through exposure to an electromagnetic field. We hope that you now know how to make a heater from improvised means at home, because both technologies were chewed from A to Z!

Related materials:

- How to make an electrode boiler yourself

- How to make autonomous heating of an apartment with electricity

- How to make a twist of wires

ALL GOOD DAY! TELL PLEASE WHO ANYTHING MADE A BOILER TO HEAT 100 KV / M? IF YES THROW OFF THE SCHEME IN MY MAIL, THANKS IN ADVANCE