The main malfunctions of machines and the causes of their occurrence

How is the protection device

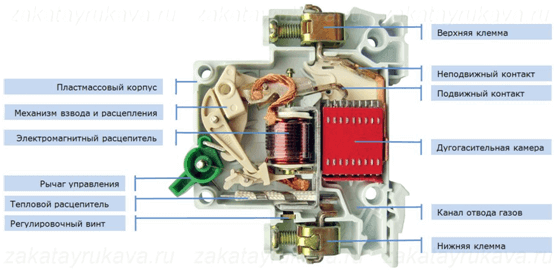

To understand the causes of all malfunctions, you need to consider the device of the machine. It consists of a pair of power contacts, a thermal disconnector and an electromagnetic disconnector.

The thermal disconnector operates slowly, with a slight (up to 2 or more times depending on the time-current characteristics of a particular circuit breaker) exceeding the rated current. Electromagnetic - in case of short circuit or excess of current several times, it works in a split second. At first glance, it might seem that there is nothing to break here, but let's look at each of the mentioned malfunctions separately.

The main problems with vending machines

The machine has only three main malfunctions:

- Knocks out.

- Does not turn off.

- Not cocked.

The machine knocks out - this means that you either suddenly, for no apparent reason, the voltage disappears, or when you turn on the load in one of the circuits, the power supply is disconnected. The machine can also not turn on in different ways:

- When cocking the lever, it immediately drops down, the voltage appears briefly or does not appear at all.

- The lever jammed and does not cock at all and does not work.

- If you heard a burning smell or the wires were burned out from the circuit breaker, it must be disconnected before starting repair, but the lever simply does not move as described in the previous paragraph, only in the on position.

The machine knocks out for no apparent reason

Periodic knocking of the circuit breaker is associated with the operation of the thermal disconnector or power surges in the power supply network. There is nothing you can do about the last reason, unless you put a voltage regulator at the input to the machine, but it's expensive. But the shutdown by the thermal disconnector is associated with a long, but insignificant in excess of the rated current.

Most often, this is not a malfunction of the circuit breaker, but rather its improper use.First of all, you should find out what current it is designed for, it is written on the front panel. Then calculate the total current consumed by electrical appliances that are powered through it. If the current is not indicated on the devices, the power consumption should appear on them, in this case, divide the number of watts by 220 V, then you will know the number of amperes through the machine.

If the result exceeds the rating of the machine - it will open. If the machine buzzes or pops, this is a sign of overload.

Decision:Reduce power line consumption, turn on powerful devices in turn.

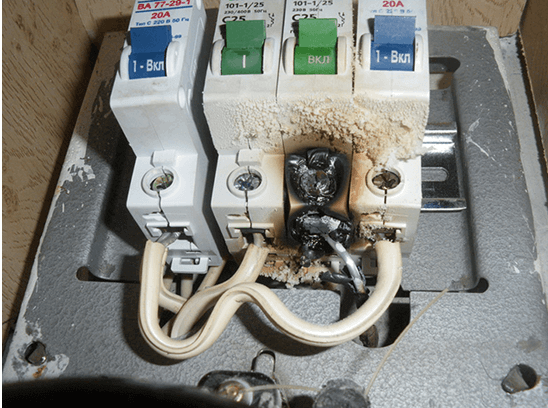

If the rating of the circuit breaker is selected correctly, the thing is different. The thermal disconnector is thermal and in order to open when overheating, and the burned-out power contacts (as in the photo below) or wires not tightened in the terminal blocks can become a heat source. Both of these lead to an increase in contact resistance, and to heating, since the case is closed, there is nowhere to go of heat, the thermal protection plate gradually heats up, with time it opens.

Decision:Check the tightness of the wire, remove, if necessary, clean them from oxidation and carbon deposits, and then tighten again. Do not clean the contacts without disassembling the machine, it is better not to “cure” this fault, but replace the circuit breaker. To disassemble it, you can drill rivets and open the case, but you run the risk of not assembling it or assembling it with errors, skew and mechanical defects, which will complicate the correct operation.

Overheating can also result from heat sources located near the AB in the shield itself. Check with your hand the temperature of the surrounding appliances, maybe something is heating nearby.

Load triggering

If a malfunction occurs when one of the circuits, for example, light is turned on, the malfunction is probably in the lamp or the wiring leading to it. Due to a violation of the integrity of the cable insulation or connections short circuit.

Decision: Diagnosis and repair consists in disconnecting the main cable of the line and replacing it with a temporary one, if it helped, it means that you will have to audit and repair the wiring.

Instant shutdown of the machine is associated with the operation of electromagnetic protection. It does not lock in the on position due to internal problems with the same electromagnetic protection. You can check the health of the machine by replacing it with a known working one, with the same rated current and sensitivity - if everything worked properly, the reason is in it. If the circuit breaker does not cock without voltage, and there is no short circuit, it needs to be replaced.

The circuit breaker does not turn on

If you raise the lever up, but the circuit breaker does not turn on, and the lever instantly falls down, this is due to either mechanical wear of the machine components or the presence of a short circuit. This can be checked by phoning the supply phase to zero with a low-impedance continuity, for example, a control lamp, or an ohmmeter. High-impedance dialing (such as LED control) can lead you astray and the circuit can ring through the load (light bulbs, electric heaters or electric motors). If the circuit is closed, then there is a breakdown of the cable insulation.

Decision:Repair by replacing the cable or restoring insulation. If there is no short circuit, then replace the machine.

The lever is jammed

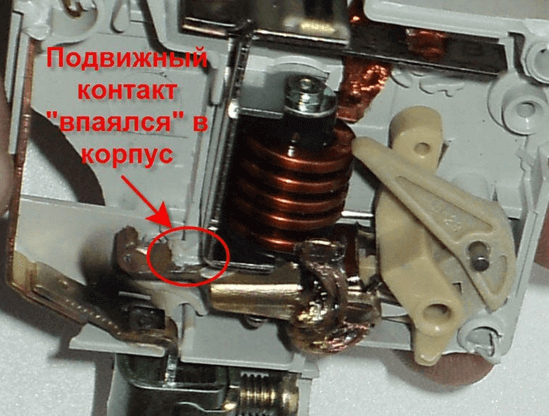

Another thing is when you cannot move the automatic machine lever from the lower position, it means that the contact drive mechanism has jammed. This malfunction can happen when disconnected under load, if there is a strong arc and its spray jammed the movable contact, or rather its components or it soldered into the body.

Decision:Grasp the lever closer to the base and lift it firmly, but smoothly, with the possibility of breaking it off. In the future, you will not be able to use such a machine. It is still likely to jam in the future, then the machine should be replaced.The probability of success in this procedure is 50%, in practice the lever often breaks off, especially if it occurs in the cold.

The machine does not turn off during short circuit

There can be two reasons for the lack of response to short circuit. The first - contacts are stuck. Due to heating and arcing during opening, the contacts adhered to each other. The second - jammed the mechanism of the electromagnetic disconnector.

Decision:If the machine does not work during short circuits, try breaking the contacts with an effort; if it does not work, then replace the machine.

How to extend the life of a circuit breaker

Remember two tips:

- Do not overload the protected line with a current higher than the rated one.

- Do not turn off the machine under load.

If everything is clear with the first tip, then the second is a bit more complicated. When current flows through the contacts and you are going to disconnect them, an arc arises. This is due to the truth of the laws of switching:“The current in the inductance cannot stop instantly.”

Even if the load is active, such as a heater, the cables have their own stray inductance. It is even more dangerous to open the circuit breaker if a load such as electric motors or lighting networks with a large number of chokes is connected to it (DRL, DNat, LL) - the inductance is still large, the arc too. Hence the contact defects, their carbonization, accelerated wear and sticking.

We got acquainted with what kind of defect caused. Circuit breakers last quite a long time if they operate within the rated conditions. Modern automatic machines cannot be repaired, therefore we do not recommend disassembling them, it is better to replace them with a high-quality analogue, for example Moeller or ABB. For household appliances and active load, use machines with the letter B, for connecting a load with significant starting currents (motor), devices with the letter D are better, and the number after the letter indicates the amount of permissible current. Do not allow oxidized wires to be connected and always tighten the terminals. Following these tips, malfunctions of circuit breakers will occur much less often, and you will not have to worry about the safety of wiring in an apartment or house.

Finally, we recommend watching a useful video on the topic:

Surely you do not know: