Test Methods for Transformer Oil

Oil Aging Assessment

For the period when the oil is used, it loses its certain indicators. In a word - it is aging and its properties are changing. How to determine if a fluid is old? The test procedure is simple: how the acid number has changed, how much sludge has formed in it and how the water extract reacts.

The acid number of a substance is a certain amount of potassium, which is necessary for the destruction and compensation of all existing free acid compounds, which are included in the structure of one gram of a substance. If you test transformer oil, you can determine the acid number, which will indicate the level of aging of the product, as well as whether such a transformer can be left at work for further operation. Due to the oxidation of the substance, the transformer loses the insulation of the windings and can collapse over time.

Sludge is formed due to the aging of the substance and if the test is carried out, it can be seen in the cooling channels, on the cores of the structure, in insulation and other electrical equipment where it is deposited. The sludge transformer is poorly cooled, and the insulation of such equipment fails and ages much faster. This in turn can lead to various accidents, such as a short in the equipment winding.

By testing the water extract, the presence of acids and alkalis that are dissolved in water can be determined. This is done thanks to indicators. If transformer oil contains alkali or acid, special indicators change color.

Checking physical properties

For the reliable operation of electrical equipment, the physical properties of the oil play a significant role. If a check of these properties showed that there are changes, this means that the equipment is out of order and the transformer oil is out of date.

The ice that forms in cold weather when the transformer is turned off falls to the bottom of the equipment and circulates the substance. The specific gravity of this ice should be greater than the specific gravity of the substance.

In order that the transformer oil does not flash and does not catch fire under heavy overloads, its flash point must be significant. And when the substance decomposes under the influence of local heating, the flash point can quickly decrease.

Electrical Analysis

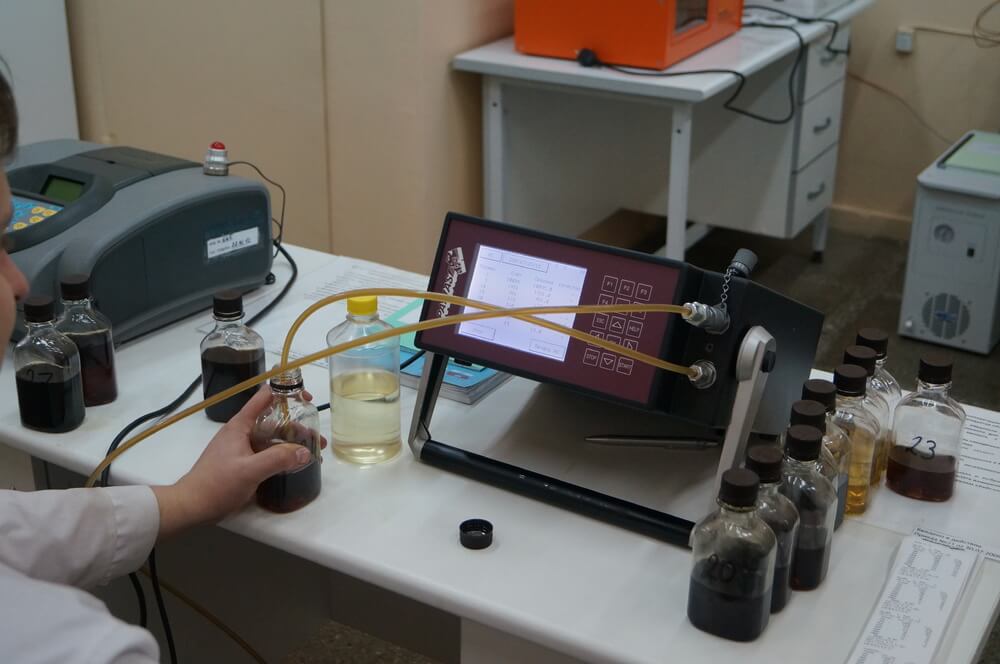

The safety of electrical equipment ensures the dielectric strength of the substance in the transformer. This indicator decreases over time. In order to check this indicator, transformer oil is tested for breakdown. This is done due to the oil breakdown unit (pictured below).

Such a unit operates from a network with a voltage of 220 V. In the design, the secondary voltage is 60 kV. The test procedure is as follows: before starting the test, the liquid is poured into a porcelain vessel, inside which two electrodes in the form of a disk are installed. The parameters of the electrodes are as follows: diameter - 25 mm, thickness 8 mm. Between them it is necessary to establish a distance of 2.5 mm. A vessel with a substance is installed in an oil breaker. In order for air to come out of it, the liquid is in the oil sump for 20 minutes. After that, at a speed of 1-2 kV per second, you need to raise the voltage.

The video below demonstrates the conduct of test work:

The test has its own frequency. It is necessary to analyze transformer oil 6 times with breaks between breakdowns of ten minutes. The first result is a trial, its testimony is not needed. The procedure for calculating the breakdown voltage is as follows: the arithmetic average of five consecutive breakdowns is calculated. If the test yields an unsatisfactory result, the fluid must be retested.

Before pouring a substance into equipment, it must be tested for the content of mechanical additives, for transparency and for stability against oxidation. In addition, it will be necessary to establish the dielectric loss tangent, the acid number, the effect of the water extract, and the flash point. Residual samples should be taken from electrical equipment that was without transformer oil from the bottom of the vessel.

Finally, we recommend watching a useful video on the topic:

So we examined with what methods they test transformer oil and its properties. We hope the information provided was interesting to you!

Recommended reading: