How to install an electric pole on a site with your own hands

Which pillar to choose

When choosing the material from which the electric pole is made, practical consideration is reduced to three options. It is a support made of wood, metal or concrete. Concrete bearings are most durable if they are manufactured in compliance with the technology in the factory. They are not afraid of the aggressive components contained in the atmosphere of large cities. Their biggest drawback is the heavy weight, which greatly complicates the installation of the support.

Metal supports are assembled from steel elements. They are used in the construction of high-voltage power lines, when the required overall dimensions do not allow the use of concrete. Note that the most affordable and cheapest is a transmission line pylon made of wood, which can be easily verified by knowing how much such a product made of metal or concrete costs.

A short list of reasons in favor of this material is as follows:

- An electric pole made of wood is much cheaper than a support made of metal or concrete. Wooden support can be made with your own hands.

- The support from a tree is the easiest. Its installation can be quite easily done without the use of lifting equipment, it organically fits into the situation in the country.

- A wooden electric pole, pre-treated with an antiseptic, has a service life, often not inferior to a concrete support. Low-quality concrete support is subject to rapid destruction under the influence of precipitation and temperature changes.

Work Stages

The installation of an additional electrical support requires a certain sequence of actions, which we will consider below. First of all, let's talk about what are the requirements for installing an electric pole on a site.So, you need to carry out the installation in accordance with current standards and rules, namely:

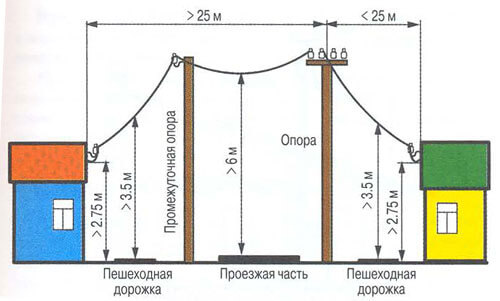

- the distance from the unprotected wire on the support to the balconies and windows should be at least 1.5 meters, and from SIP - at least 1.5 meters;

- on the offshoot uninsulated cable should not be lower than 2.75 meters from the ground to the inputs to the house, and SIP - 2.5;

- above the roadway, the power line should be located at least 6 meters, above the roadway - at least 3.5 meters;

- the structures on which the current conductors are installed must be made of non-combustible materials (a wooden pillar must be impregnated with a protective composition that does not support combustion);

- the distance from uninsulated conductors to the pipeline for any purpose should be at least 1 meter, while if the wire is insulated, the distance is not standardized;

- insulators on supports should be made of porcelain or glass.

As for the technology of installing an intermediate support on the site, it looks as follows:

- In accordance with the issued technical specifications, the place where the electric pole should be installed is selected.

- Depending on the nature of the soil, a hole is drilled or manually digged into which the support will be installed. If the support is no longer than 10 meters, a sufficient depth of the pit is 120 - 150 cm.

- In the case when a wooden electric pole is installed directly in the ground, the underground part of the support is pre-treated with bitumen mastic. When using a concrete stepson, the latter must be attached to the support before installation is carried out.

- Next, the support is mounted in the prepared pit. The position is controlled by a level and is fixed by filling the pit with gravel and ramming it.

- You can finally fix the electric column by filling the free space of the pit with concrete, or confine yourself to packing with crushed stone.

We offer you another option for installing an intermediate wooden support in the country. All that is needed is to make a pillar, at one of the ends of which a cross is assembled, measuring 2 * 2 meters. The connection of the cross with the end is carried out in half the tree using galvanized corners. Next, you need to make four jaws, as shown in the photo below. After that, a home-made wooden support is painted over with bitumen mastic to a height of about one and a half meters. The last stage of the installation - a cruciform pit breaks out, the column is mounted, aligned according to a plumb line or level, and then backfill / ramming the soil.

Installation of wiring in the house

The branching from the power supply line to the intermediate support can be performed in several ways:

- bare aluminum wire;

- copper or aluminum cable;

- self-supporting insulated wire (SIP).

In the first embodiment, a traverse with insulators on which the wires are mounted on the electric pole is installed. If the section from the intermediate support to the direct entry into the house is also made with bare wire, a traverse with insulators should also be installed on the house. Also, in the area between the pillar and the house, a cable can be used that is mounted underground or over the air using a steel cable.

If a cable is used from the overhead line to the intermediate support, the need for traverses and insulators disappears, it is enough to install the fastening on the VL support and our column for the steel cable on which the cable will be mounted. About how to lay a cable on a cable, read the article:https://my.electricianexp.com/en/texnologiya-prokladki-kabelya-na-trose.html.

The third option using the SIP wire encompasses new technologies and carries a number of advantages:

- Using SIP installation of a supporting steel cable is not required, as is the case with the cable, since the wire is self-supporting and can withstand all mounting and operating loads.

- The CIP shell made of cross-linked polyethylene successfully resists weathering, ultraviolet radiation and temperature changes.

- The advantages of SIP over bare wire are obvious - it is reliability and safety.

Finally, we recommend watching a video that shows how to install an electric concrete pillar manually and by a specialized organization:

Now you know how to install an electric pole on a site in accordance with current norms and rules. Nevertheless, we do not recommend to do the installation with our own hands, it is better to entrust this matter to specialists if it is not about a wooden intermediate support in the country.

Useful materials on the topic:

Please tell me, we have 25 meters from the main pillar to the house, we have not installed an additional pillar. We have a strong sag, less than 6 meters above the roadway. We live in a village.

And how do you need help? Let them try to pull the wire harder, in the heat it will sag even lower. In general, apparently you still need to put additional support near the road.