How piercing clamps work and why they are needed

Clamp purpose

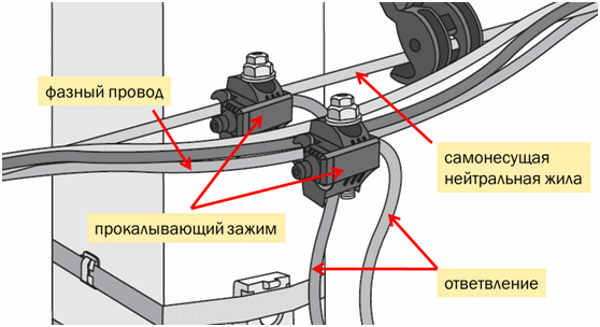

In the vast majority of cases, the piercing clamp is used to enter electricity, connect to the overhead power line without removing the voltage (without disconnecting). The main element of the clamp is a contact plate with sharp teeth. During installation, they puncture the insulation of the trunk wire and branch cable, providing electrical contact.

At the same time, there are options for clamps for branches between an isolated and non-insulated (bare) core. On the side for connecting the bare core there are no teeth for puncture the insulation. Electricians simply call such clamps - nuts.

Another wire coming out of them is fed to the input circuit breaker for further wiring of the electrical network in the room.

Device and principle of operation

The clamps consist of a housing in which conductive pads with piercing teeth are placed to connect two conductors, or teeth are located on one side and grooved jaws on the other side for connecting a bare main wire. However, different manufacturers have different products, so the design and installation features may vary.

There are several fundamental factors that you need to have an idea about installing a piercing clamp for a SIP wire:

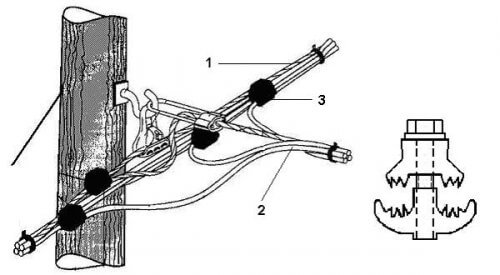

- Two veins are threaded through the clamp. In this case, a large hole is put on the trunk, and a branch core is inserted into a small one (usually the branch cross section is several times smaller than the main line section.

- The clamp most often has 1 bolt with a stall hat. It is tightened with a head or key (preferably with an insulated handle) until the hat comes off. This way you tighten the connection to the rated torque without using a torque wrench.

If the clamp is tight, then its outer part is usually covered with dielectric material. So it can be installed anywhere on the line, if the clamp is leaky - it is better to install it closer to the support, but not in the middle of the line, where it sags, because water flows there during precipitation.

Nevertheless, the CIP cable mounting technology suggests that branch clamps are usually installed together with tension anchors, as shown in the figure below.

Installation Rules

Uninterrupted quality when using clamps for SIP wire is due to their manufacture according to modern technologies and integral quality control of finished products at all stages of production. Based on the use of quality materials, the service life of the SIP puncture is about 30-40 years.

When installing the branch clamps for the SIP wire, it is necessary to pierce through the insulation located on the cores. Assumptions that this will serve as a negative criterion for the entire strength of the electrical installation are erroneous. Before work it is necessary to make sure that the puncture mount point is tight.

The main installation rule is that you cannot use disposable products. The fact is that after the cap of the tightening bolt is broken, a hexagonal base remains, with which some electricians try to tighten the clamp for reuse.

However, even if it succeeds in doing this correctly and with the right moment, then most likely there will not be good quality contact, because the piercing teeth are designed for single use, after which they bend or blunt.

You can find out how the product is installed by watching the video:

Types of products

Clips can be of different types and designs, but you can classify them as follows:

- The permissible cross-section of the connected wires. Usually with one bolt up to 95-120 mm², and with two bolts - for thicker cores, for example, up to 240 mm² (but not always).

- Single-bolt and double-bolt (the permissible cross-section for the connection and the permissible current through them are different).

- Sealed and leakproof (protection classes may be different, according to IPxx classification).

- For connecting an insulated wire with a bare wire (a puncture only from the side of one of the cores), for connecting two isolated SIPs (there is a piercing part on both sides).

Approximate nomenclature of different options for piercing clamps:

When purchasing a piercing clamp for a SIP wire, it must be remembered that the head of the bolt must correspond to the wrench used when working with it. In most cases, the head has a size of 13 mm, but sometimes there are also varieties with a bolt size of 17 mm. The marking of the clamp contains information on the minimum and maximum cross-section of the wire that can be drawn through it. This size is also used for information on the thickness of the trunk. The choice of the necessary model of a piercing clamp for an SIP wire becomes absolutely simple if you are guided by the above information.

Finally, we recommend watching a video that tells what the clamping mechanism is for self-supporting insulated wires and how they are mounted:

So we examined the installation features, purpose and principle of operation of the piercing clamp for SIP wires. We hope the information was useful and interesting for you!

We also recommend reading: