How to test cable lines with high voltage?

Typical Cable Damage

According to statistics, the most common damage that causes electrical cable failure is:

- Damage to the integrity of the containment as a result of improper technological work.

- Damage to insulation due to aging of the material of which the cable is made, due to violation of test technology.

- The appearance in the protective screen of cracks and tears that violate the insulation function.

Varieties of tests

In accordance with the accepted norms and rules for testing electrical equipment, it is necessary to make sure that the declared cable characteristics meet the requirements. If any discrepancies are revealed, it is strictly forbidden to make change and especially to exploit such lines.

Types of tests:

- Insulation failure is checked by determining the value of its resistance using a device called a megger, applying a voltage of 2.5 kV. If the insulation resistance turns out to be higher than 500 kOhm, then it is considered that this is sufficient for cable lines up to 1000 V. If the voltage is more than 1000 V, there is no rationing, but according to the PTEEP (clause 6.1. And table 37) and PUE (clause 1.8.37 and table 1.8.34), the value should not be lower than 10 megohms. More about how to use a megaohmmeter, you can find out from our article.

- Damage can be detected by conducting high voltage tests. In this method, observe leakage currents, namely their phase asymmetry and character. This method is more effective, because it allows you to identify damage to the insulation, which were not detected using a megger. Increased load produces breakdown in problem areas. To carry out such a test, voltage is applied to one of the cores of the cable, and the remaining cores and the sheath are grounded.

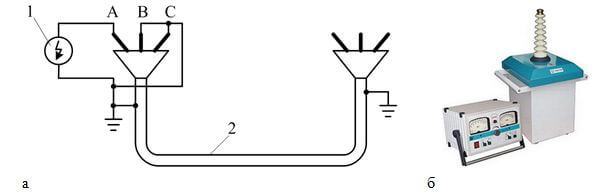

The figure above shows: a - electrical circuit for checking insulation; b - shows a high-voltage installation for testing. In the diagram:

- 1 is a generator (source) of increased load;

- 2 - conductor checked for integrity.

Different types of insulation require a certain amount of time to establish breakdown.So, for example, testing a cable line for an increased voltage of 2000-35000 V requires 5 or 10 minutes of a constant load for each core. If the tests are designed for a cable line rated for 110,000-500,000 V, the voltage is supplied to the cable for 15 minutes. During the test, the asymmetry of the current distributed in phases shall not exceed 50%.

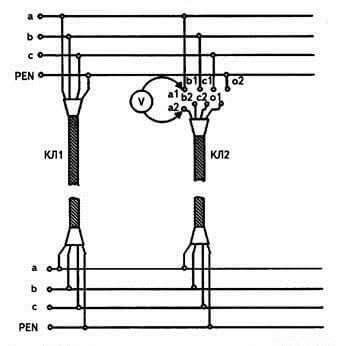

In the case of cable operation in parallel with the other, it is necessary to carry out its phasing. This is achieved by applying the operating voltage to one end of the cable and measure voltage at the other end.

- A high-voltage line with oil-filled insulation, which is usually used in highways where a load of 110-500 kV is transmitted, passes the test of oil or other liquid filling it for compliance with the declared characteristics.

- The cable high-voltage line is checked for protection against corrosion:

- When the cable has a metal sheath, and the products are used for laying in the soil, its specific resistance does not exceed 20 Ohm / m.

- When the conductor has a metal sheath, and the products are used for laying in the soil, its specific resistance is less than 20 Ohm / m.

- When the shell is armored and it is necessary to check for damage, as well as the destruction of the protective cover.

- When the cable is designed in the high pressure zone of steel pipelines, and the soil has a different degree of aggressiveness. The high-voltage cable communication line is subjected to measurements of the potentials and currents wandering in the shell.

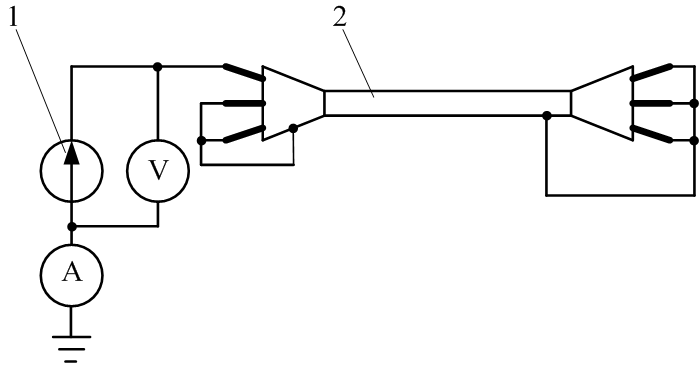

- The cable high-voltage line is checked for the integrity of conductive conductors, as well as phasing using an ohmmeter device. Why one core is determined and relative to it they continue to be carried out, in turn, measurements of the resistance of the closed circuits of all the wires. A known intact conductor can be used as a reference core.

where: 1 - instrument ohmmeter; 2 - item to be tested.

- A high-voltage line, designed for operation at an increased voltage of 20,000 V or more, it is necessary to set the resistance value of each individual core of the cable being tested.

- Check for current distribution across the cores. The value of the unevenness in the veins should not exceed more than 10%.

- The high-voltage cable communication line (from 110,000 V to 500,000 V), which has oil-filled insulation, is subjected to the determination of insoluble gas content. For such highways their value should not exceed 0.1%.

- The cable line, where there is an increased voltage of 20 kV and above, is subjected to the determination of the value of electric capacitance. As a rule, in such cases, two methods are used: using a multimeter, using the determination method using the bridge circuit.

1 - load source; 2 - item to be tested.

- A high-voltage line (from 110,000 V to 500,000 V) with oil-filled insulation must be checked for gas contents not only insoluble, but also soluble. For this, a chromatographic method for the determination of such substances is used.

- Also, resistance tests of grounding devices, end and cable terminations, metal structures that make up the cable wells, as well as make-up points, are performed.

- High-voltage cable communication lines (110,000 V), the shells of which are made of plastic, are tested for 1 min by applying increased rectified voltage.

What else is important to know?

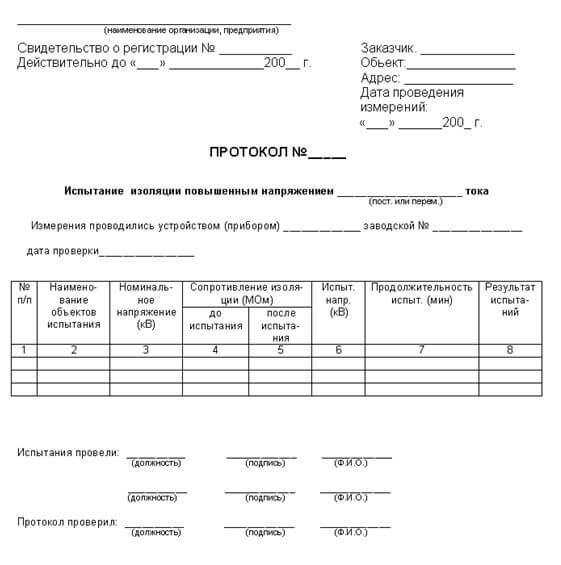

After testing, the result is entered into the protocol, such as on the sample:

Regarding the timing of the tests, they are as follows:

Well, it’s important to say that such devices as IVK-5, AID-70 and AII-70 are most often used for work!

Finally, we recommend watching a useful video on the topic:

So we examined how the cable is tested with increased voltage.Now you know why it is necessary to carry out checks and what methods exist today!

We also recommend reading: