Wire Cross Section Determination - An Overview of Effective Techniques

The important point is that even if you correctly carry out all the calculations and select the right product, such a nuisance as an accident can still occur. This is due to the fact that the cross section of the wires, which is indicated on wire markingcorresponds to the actual values. This is the fault of the manufacturer only, because, undoubtedly, the characteristics do not coincide due to any economic "tricks" in the company. Sometimes wires and cables on the shelves generally without labeling, which also casts doubt on their quality.

You ask: “Why should a company spoil its reputation?”, To which you can immediately find several logical answers:

- The plant decided to save on the quality of the goods. For example, if you make a 2.5-mm strand thinner by 0.2 mm.sq., you can win several kilograms of metal per 1 linear kilometer. With mass production, savings have decent numbers.

- In the struggle for a “place in the sun”, electric wiring companies are trying to lure consumers to themselves, making the price lower than their competitors. Accordingly, a low price is set due to a slight reduction in diameter (not noticeable by eye).

As you can see, both of these answers are quite reasonable, so it’s better to warn yourself and do some simple calculations, which we will talk about later.

Determination methods

There are several ways to determine the cable cross-section. They all boil down to first calculating the diameter of the core, and then using small calculations to find out the final value.

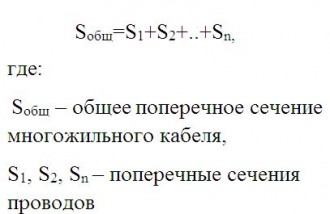

Method number 1 - Instruments to help!

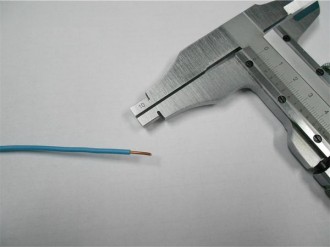

To date, there are engineering devices with which you can easily determine the diameter of the wire or cable. Such instruments include a caliper and a micrometer (enlarge the photo by pressing to view all the tools).

- Mechanical micrometer

- Electronic micrometer

- Mechanical vernier caliper

- Electronic caliper

This method of determining the most accurate, but the “reverse side of the coin” is the cost of the caliper / micrometer itself. The price, of course, is not cosmic, but for a one-time use, it makes no sense to purchase this tool.

Most often, this option is chosen by professional electricians, whose life is directly related to wiring installation. Having a caliper, you can most accurately determine the cross section of the wire on your own. The advantage of this technique is that it is possible to measure the diameter of the cores even on a section of a working line (for example, in a socket).

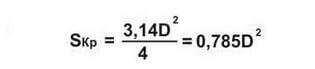

After measurement, you must use the following formula:

Do not forget that the number "Pi" is 3.14. For maximum simplification of the formula, 3.14 can be divided by 4, after which the calculations will be reduced to multiplying 0.785 by the diameter squared!

Method number 2 - Using the ruler

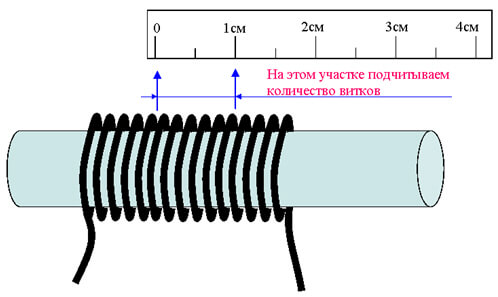

If you don’t want to spend money (and you’re doing it right!), Then we recommend using a simple “grandfather” method in order to determine the wire cross-section by its diameter. If you have wire, a simple pencil and a ruler, you can find the answer in a matter of minutes. All you need is to strip the core from insulation, then tightly wind it onto a pencil (as shown in the picture) and measure the total length of the winding with a ruler.

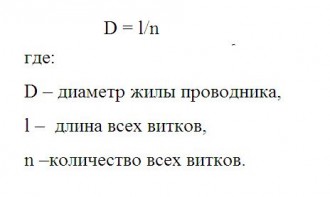

The essence of the method is that it is necessary to measure the total length of the wound conductor and divide it by the number of cores. The value you get is the diameter you need to determine.

Despite its simplicity, calculations have their own peculiarity:

- the more veins will be wound on a pencil, the more accurate the result will be, the minimum number of turns is 15;

- the turns must necessarily be pressed closely to each other so that there is no free space, which will significantly increase the error;

- determination must be carried out several times (changing the initial side of the measurement, turning the ruler, etc.). Again, the more calculations, the less error.

We draw your attention to the significant disadvantages of this method. Firstly, only thin conductors are suitable for measurement (for reasons that it will be difficult to wind a thick cable). Secondly, in the store before buying for such a technique, you must separately purchase a small piece of the product.

After all measurements, you must use the same formula that we indicated above. The video shows an example of determining the cross section of a conductor using a ruler:

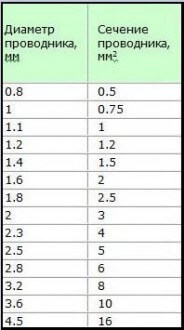

Method number 3 - Using tables

Instead of determining the cable section according to the formula, you can simply use ready-made tables that will reduce your time and make the result most accurate.

The table is quite simple: in one column the diameters of the cores are indicated, in the second - their cross sections in squares.

Tips from an electrician

We have provided existing methods, but there is more to come.

We recommend that you familiarize yourself with the following tips from experienced electricians on determining the cross section of a wire:

- In addition to the cross section of the product, pay attention to the metal core. Copper or aluminum core should have a characteristic rich color. If the color is doubtful, then most likely it is an alloy of metals, which allows you to save your money to the manufacturer. Such an alloy is extremely dangerous for wiring in the housebecause its conductivity and rated loads are several times less than those of the original product.

- The section should be determined only by the vein. Even if the product looks normal in thickness, it is possible that the reduced core dimensions were compensated by an increased insulation layer.

- If you doubt the size of the conductor, get a larger wire section. Power reserve does not exactly hurt your wiring!

- If you are dealing with a cable, the calculation will be slightly changed (due to the fact that the cable may consist of the nth number of wires). To correctly carry out the calculations, you must first determine the diameter of each individual wire, then summarize all the values and select the product according to the total number.

Video instruction

We found a very interesting video instruction, which shows not only how to determine the cross section of the wire, but also a clear example of different quality products from several manufacturers. If you know the Ukrainian language, then the video will be useful to you and will be able to answer your questions, if any!

Also read: