How to terminate the wire lug?

It's important to know

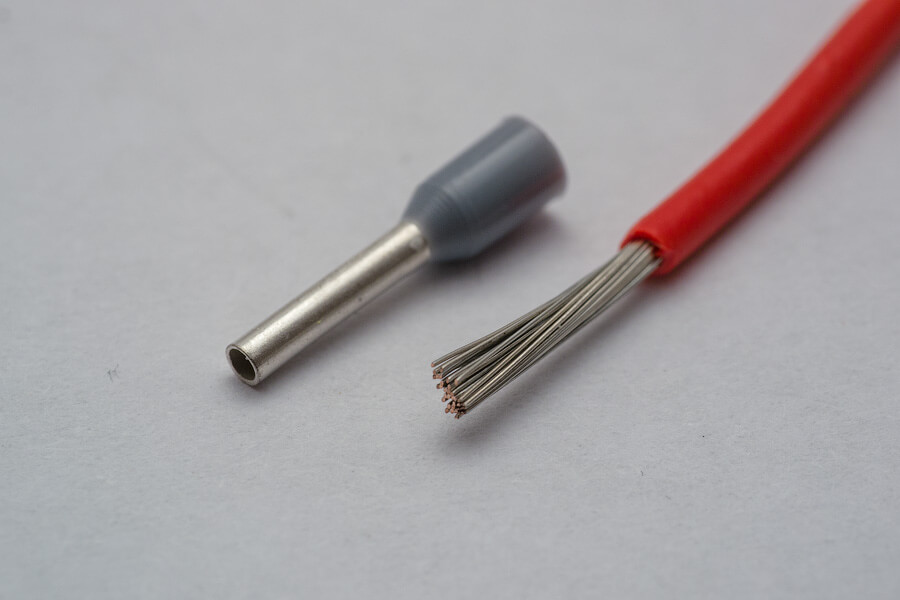

The first thing I would like to talk about is the importance of terminating the conductors of wires and cables with a special tool and why do I need to crimp the conductors with lugs. Surely you paid attention to how it connects ground bus to the housing of the switchboard. The yellow-green wire is fastened on both sides by a screw connection through a special tip, as shown in the photo below.

Not so long ago, instead of such a tip, the core simply bent with a ring using pliers and was tightened with a screw. Some woe-electricians simply inserted a wire between the screw and the plate and carefully clamped with a screwdriver. It is strictly forbidden to do so, as with this method of ending the cores, the transient resistance increases, as a result of which you can see the fused cable insulation, which can lead to a short circuit in the wiring or more serious consequences - the occurrence of a fire in the house.

Another very unfavorable consequence of dysfunctional vein fastening is the burning of zero at high current loads. ABOUT consequences of burning off the neutral wire You can find out in the corresponding article!

Termination technology

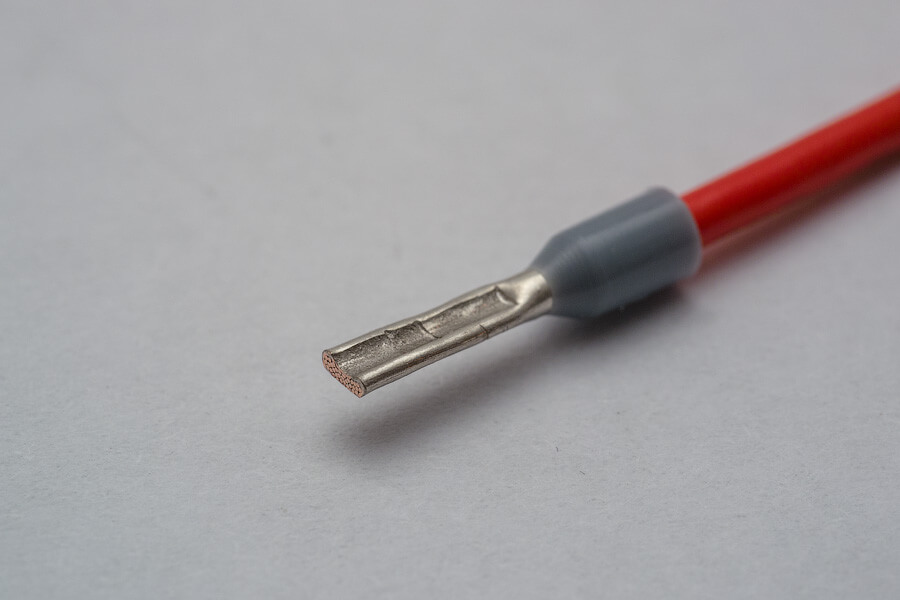

Independently terminate the wire or cable with a special tool will not be difficult. You just need to take a suitable tip, put it all the way onto the core and compress it with a press. The number of crimping points depends on the design of the crimping tool. If crimping is carried out using a matrix with a point contact, squeeze the tips in 2 or more places distributed along the length. If the tested part of the tip is comparable with the indentation width after crimping, then one point is enough. The sleeves are crimped with at least two indentations, one on each side to hold each of the conductors. In general, the number of crimping points depends on the width of the “jaws” of the crimping tool matrix.

This is for better contact, minimal transition resistance and mechanical strength. In simple words - in this case, you will not jump out the conductor from the tip or sleeve.

Pay attention to the recommendations given in the instructions or in the appendix to the crimper (crimping, pressing pliers), regarding working with tips of different diameters or sections.

Rules and technology for terminating and crimping conductors are described in the following documents:

- BCH 139-80

- I1.09-10

In addition, an important requirement should be noted - for crimping an aluminum conductor, quartz-petrolatum grease must also be used, which prevents the formation of an oxide film that impairs contact.

At home, it is not always wise to buy an expensive tool for crimping, so there are alternative options. For example, there is a special wire stripping tool and cables - a stripper, the design of which may include a press, as shown in the photo.

You can also do without the so-called pincers - manually flatten the sleeve with a hammer or pliers, but in this case there is no guarantee of good contact, so it’s better to waste at least a stripper for reliable termination of the wires, and even better crimper (special crimping). About, how to use a stripper, we told in a separate article.

We draw your attention to the fact that if you decide to terminate a single-core conductor with pliers, you must correctly select the crimp die. With the wrong selection, there is a high probability of spoiling the sleeve or tip simply by tearing its metal.

In addition, there are special solder tips. In this case, the termination of the conductors of the wire or power cable occurs in two stages:

- The core, stripped to a metallic sheen and treated with a neutral solder, is inserted into the tip until it stops.

- Solder is poured through a special hole.

Briefly about tips

Well, the last thing I would like to talk about is with what tips you can terminate the wire and cable at home. Today, in industry and in everyday life, the following products for termination are popular:

- ТМ - copper, without coating;

- TML - tinned copper electrolytic;

- TML (o) - additionally there is a control window that allows you to visually determine whether the core has completely entered the tip;

- TAM - aluminum-copper, allow you to safely attach the aluminum conductor to the copper bus;

- TA - aluminum;

- PM - copper, soldered;

- NShP - pin, used for connecting circuit breakers and other protective automation of the latest models with a crimped pin;

- NB - tips with stall bolts, allow crimping by tightening the bolt, as a result of which you rip off his hat. After that, it will not work to unscrew the bolts, and the core termination will turn out to be quite high quality.

So we have listed the most popular types of lugs that allow you to terminate the conductor for safe connection to buses and electrical appliances. It should be noted that the connection using crimping is allowed in PUE 2.1.21 (Chapter 2.1 of the PUE), unlike twists! One of the most important points is the correct choice of the tip or sleeve for the section of the conductive core. If the tip is too large, it will not work to achieve good contact; if it is too small, the vein will simply not fit into it. Also, do not compress large tips with significantly smaller dies! And crimping with too large a tool will not provide reliable contact.

When choosing tips, pay attention to their marking, which is as follows:

TM (for example) -XX-YY, where:

- XX - conductor cross section for crimping;

- YY is the diameter of the hole for the clamp bolt.

Also read:

outgoing from the copper bus through a bolt with washers, copper, single-wire does he need a tip? why unnecessary contacts? can I just squeeze between the washers?

Links are given to inactive documents AND 1.09-10 and this document BCH 139-80 Instructions for the construction of cement concrete coatings ... in general does not apply to this topic