Electric underfloor heating for a wooden house

- What is important to know?

- On a wooden base

- Infrared film

- Cable on mounting plate

- Installation of a detachable cable on logs

- On a concrete base

- Laying the heating cable in the screed

- Installation of heating mats in tile adhesive

- Installation of mats on a wooden base with a screed

- Foil mats for mounting without screed

What is important to know?

You can install a warm floor in one of the following ways:

- on the existing wooden floor;

- on a wooden floor with an air gap (on the logs);

- on a concrete base;

The choice of heating system will depend on whether cement, leveling compound, tile adhesive or mastic are required - that is, “wet” installation. The following types of heating elements are suitable for heating a wooden floor: infrared film, cable on the mounting plate, cut-off cable, heating mats.

Looking ahead, we note that the installation of heating mats requires a concrete base or a cement-sand screed. It is not possible to foresee this in every wooden house, except perhaps on the ground floor. Infrared film and cables on the plates can be installed on wooden flooring. Cut-off heating cable can be laid both in a screed and in a dry way (on logs). In the latter case, it is extremely important to correctly calculate the power. And here you can look at specific warm floors for a wooden house, which are suitable for the situations considered in the review.

On a wooden base

According to the requirements of European standards, cable heating systems with a specific power of 100 W / m2 or more are prohibited for installation on a wooden floor base. Infrared films are not subject to such restrictions.

Infrared film

IR films are universal: they can be mounted on the floor, ceiling, walls. Available in 150 and 220 W / m2.

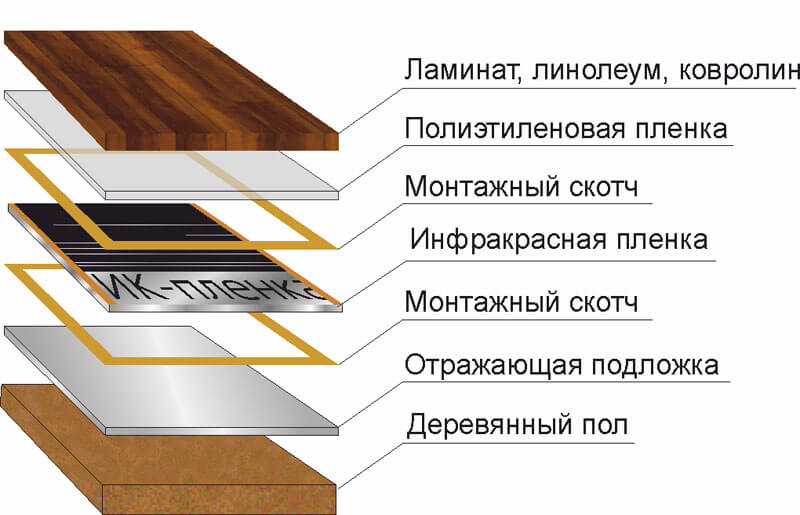

| Dry installation of infrared film on a wooden floor

|

Products: Lavita LH, Q-Term KH, Heat Plus, RexVa Xica, KS-PTC. |

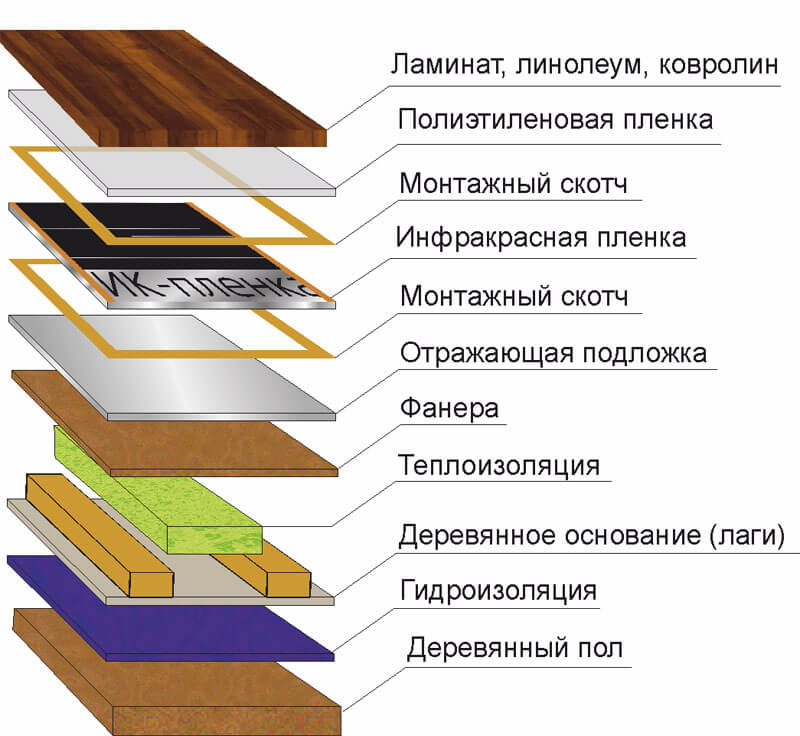

| Dry installation of infrared film on a wooden floor on logs

|

Similar products: Lavita LH, Q-Term KH, Heat Plus, RexVa Xica, KS-PTC. |

The listed IR films are produced in South Korea, as, however, the vast majority of those on sale. In Europe, the use of infrared film is not practiced. Perhaps the whole point is that there are no bans on the use of infrared film heating systems in existing European standards in Asia.Manufacturers themselves vying declare the safety of IR film and a long service life. Supporters of this easy-to-install and inexpensive (cost of 1 mp film - from 325) system have many arguments in favor of security. For example, this: heating of an infrared warm floor is controlled by a temperature regulator, which will prevent the film from overheating.

It's important to know: The film should not be installed where the furniture will stand. An exception is KS-PTC. It costs more, but thanks to the self-regulation effect, it can be installed around the entire perimeter of the room. Installing an infrared film under a tile is difficult: after all, tile adhesive cannot be applied on top of it. It will be necessary to create a complex multi-layer “pie”, we do not recommend weighting the wooden floor!

Cable on mounting plate

Unfortunately, this method of mounting on a plate is not very popular, so the range is small.

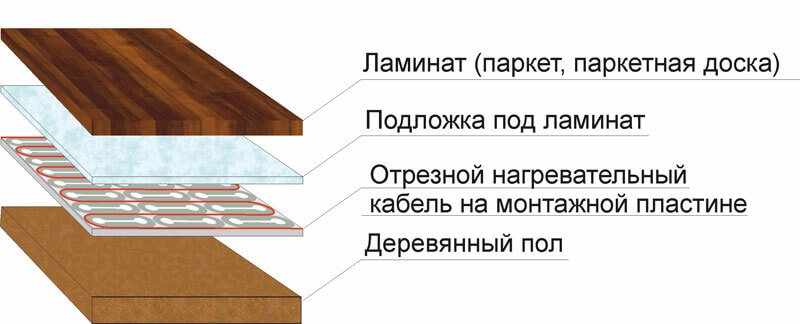

| Dry cable installation on a mounting plate on a wooden floor

|

Products: U-RD-B (Raychem), Deviflex 10T (Devi). |

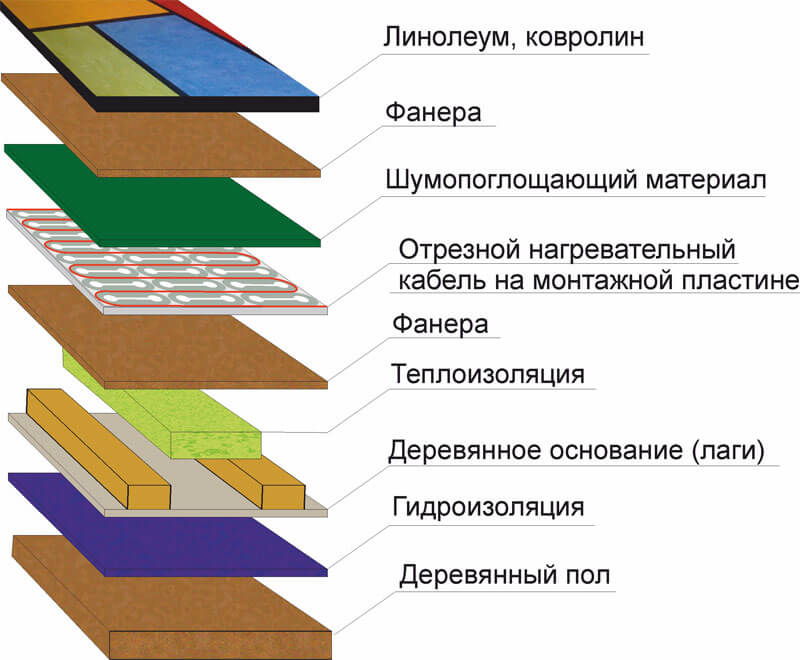

| Dry cable installation on a mounting plate on a wooden floor on logs

|

Products: Deviflex 10T (Devi) |

Improvements for the Devi system: 6-10 W / m resistive cable and DEVIcell ™ Dry mounting plates with grooves for cable management are used. The manufacturer recommends installing an waterproofing layer when installing under parquet or laminate on a wooden floor. If the heating is installed on the lags for decorative coatings, such as: linoleum, vinyl, carpet, laminate, then it is necessary to add sound-absorbing material and a shield that distributes the shock load to the structure.

But the U-RD-B cable on R-RF Raychem plates can be installed directly on the base of the wooden floor. Parquet, parquet board or laminate is recommended as a topcoat. You can also lay it under the tile, only you have to change the installation scheme: add a primer over the cable and an adhesive layer for the tile. Raychem U-RD-B differs from other analogues in its high price, excellent quality of components and self-regulating cable, which allows you to save up to 20% of energy when heating the floor. Calculation of power (35-100 W / m2) of a self-regulating cable is based on how well the base is isolated from heat loss.

From similar systems, the Danish DVC-10 cable (Heandy Haet) sometimes appears on sale, which, like Devi, can be attributed to the middle price category (a heating kit with a mounting plate will cost about 7000).

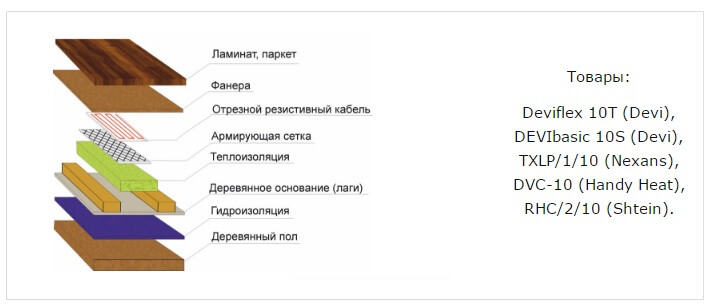

Installation of a detachable cable on logs

Cable installation on logs for wooden houses is the most common option. It is not too laborious, and the price does not “bite” (about 3000 for a set of European cable for heating 1 m2 of floor). In wooden floors and other constructions of combustible material, the specific power of the heating system should not exceed 60-80 W / m2 with a linear power of the cable not more than 10 W / m, the installation step is chosen within 90 - 130 mm.

The height of the air plug between the insulation and the floor (plywood) should be 30 mm, the distance between the cable and the floor - 10 mm. The cable should be laid evenly over the entire area of the heated surface.

On a concrete base

If a concrete floor is mounted on the ground floor of a wooden house or a wood screed is installed (taking into account existing rules and restrictions), then the choice of a heating element for a warm floor becomes wider.

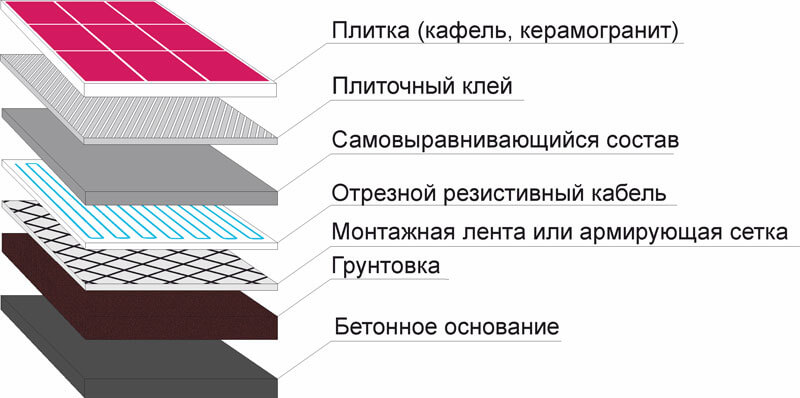

Laying the heating cable in the screed

Before buying a detachable cable for mounting in a screed, it is important to correctly calculate the power and the laying pitch. Under the tiles and porcelain tiles use a heating cable with a specific power of 10-20 W / m.

|

|

Products: SVK-20 (Thermo), Deviflex 10T (Devi), TXLP / 2/17 (Nexans), TXLP / 1/17 (Nexans). |

The scheme can also be used for installation under a laminate, linoleum, carpet, but instead of an adhesive tiled layer, a sound-absorbing substrate for a laminate is installed. For wooden flooring, it is recommended to use a cable with a specific power of 6-10 W / m.

Recommended power for a comfortable concrete floor heating system is 60-100 W / m2. The maximum thickness of the base is 50 mm, the layer of self-leveling composition (screed) is 30-80 mm. In cold rooms, provide thermal insulation of the base.

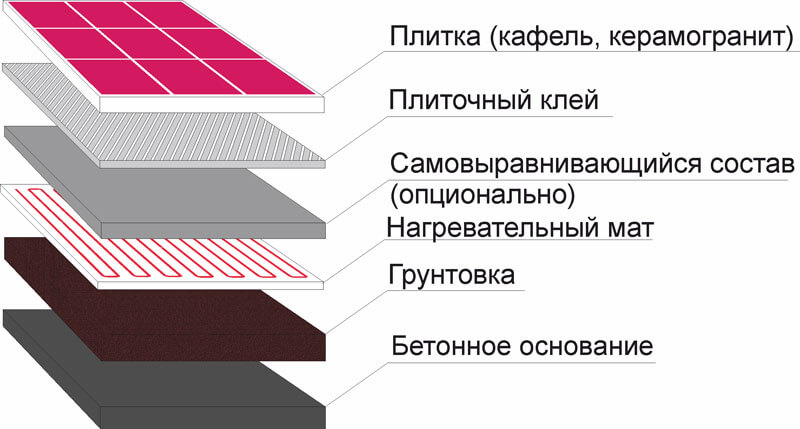

Installation of heating mats in tile adhesive

|

|

Products: Thermomat TVK-130 (Thermo), "National Comfort 2NK" (CCT), Heatus M-B (Heatus), Lavita mat (Lavita). |

The heating mats listed above as examples for mounting under a tile have a power of 130-170 W / m2. The scheme can also be used for installation under a laminate, linoleum, carpet, but instead of an adhesive tiled layer, a sound-absorbing substrate for a laminate is installed. For wooden flooring, it is recommended to use mats with a capacity of 80 W / m2. The cost of mats starts from 2000 per sq. m

This scheme is similar to the previous one, except that the mounting grid is not required, since the mat is supplied in the form of a cable already attached to the grid with the desired installation step. Due to this, cable nets (heating mats) are widespread and are sold as a turnkey solution for underfloor heating. An installation pattern may eliminate the use of a self-leveling layer. In this case, tile glue (mastic) is applied immediately to the fixed mat, and immediately tile is neatly laid on top. You should consult the instructions, since all manufacturers establish their own rules. So, for Thermomat mats the recommended thickness of the adhesive solution is 3-4 cm, for National Comfort mats - from 8 mm, for Devi products - 3-5 cm.

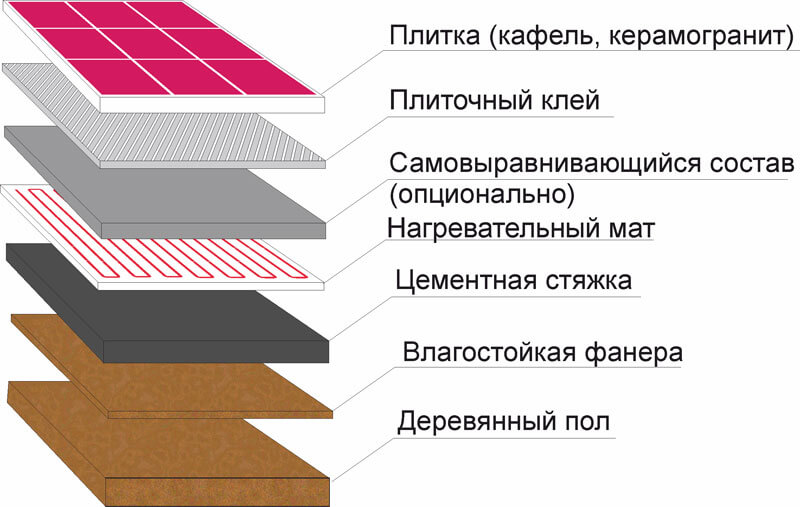

Installation of mats on a wooden base with a screed

Some manufacturers allow the use of 150 W / m2 specific power mat on a wooden floor with a screed. Here is an example and installation diagram:

|

|

Products: DEVImat 150T (Devi), Warmstad WSM (CCT). |

The scheme can be used for installation under a laminate, linoleum, carpet. Instead of the adhesive tile layer, a noise-absorbing substrate for the laminate is installed, and the mat is poured with a cement-sand screed of 3 cm. The rough wooden floor must be firmly fixed.

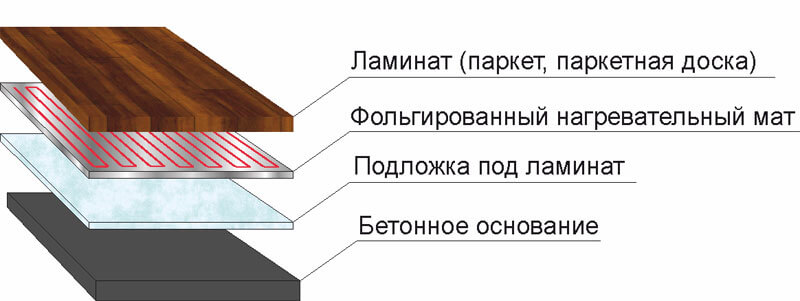

Foil mats for mounting without screed

If the base of the floor is concrete or a cement-sand screed is installed, it is convenient to use Devidry, Thermo LP heating systems that are easy to install (power from 100 W / m2). An important rule works here, which is noted in the installation and operating instructions by European manufacturers of these cable systems: it is forbidden to use products with a capacity of more than 80 W / m2 in rooms with a wooden floor.

|

|

Products: Devidry (Devi) *, Thermomat TVK-130 LP (Thermo). |

As a substrate, Devi recommends installing a vapor barrier.

Take note of these brands and use them for dry installation in the case when the floor in the house is concrete and the finish is wooden. Their installation diagram is very simple (similar to installing a cable on a mounting plate), the price is from 3500 per sq. m

The installation diagrams do not show the installation location of the sensor, thermostat, supply cables. These are important steps to follow when referring to the installation manual for the product. To prevent cracking of the wooden flooring, a thermostat with air and floor sensors should limit the maximum floor temperature to 35 degrees. C.

When choosing the type of heating element, carefully read the instructions for its installation. The type of subfloor and type of finish are important criteria when deciding whether to purchase a warm floor. Carpet, linoleum, parquet board and other coatings must withstand temperatures specified in the product documentation. Therefore, the compatibility of the cable system with one or another type of decorative coating should be specified in the instructions of the specific manufacturer. Some manufacturers of heating systems strictly regulate the type of substrate, heat and waterproofing layers.

To decide on the choice of materials for the heated floor in a wooden house is a complex.If the house is still being designed or built, the field for activity is much wider: you can provide a concrete base, lay the thickness of the structures and additional loads. More expensive dry installation options can be used at any stage of home insulation.