What is a thermal relay and what is it for?

Design

To begin with, we will tell you what the thermal protection relay consists of. The basis of the RT is the phenomenon described by the physical law of the Joule-Lenz:

The amount of heat generated in a section of an electric circuit is proportional to the square of the current strength and resistance of this section.

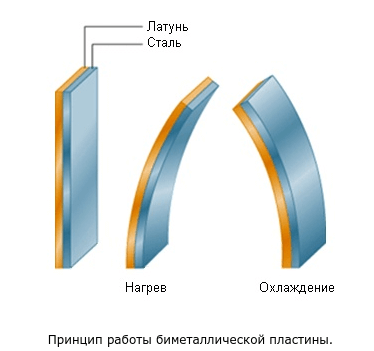

This phenomenon has been successfully used in a thermal release. A short section of the circuit, acting as a heat emitter, is wound with a spiral on the insulator. All current passing through the electric machine passes through this section. Directly next to the spiral is a bimetallic plate, which, when heated, bends and acts on the contact group. The plate consists of two dissimilar metals having different expansion coefficients during heating, combined into one element.

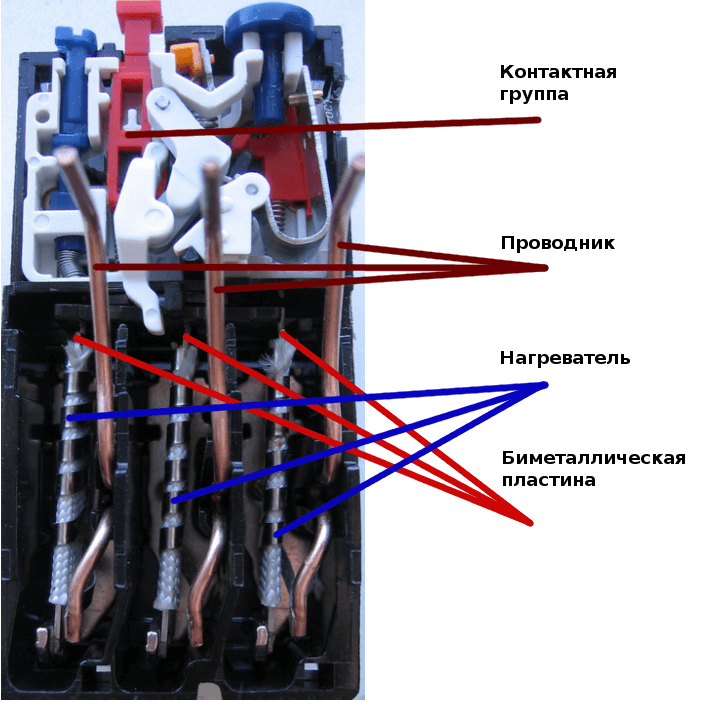

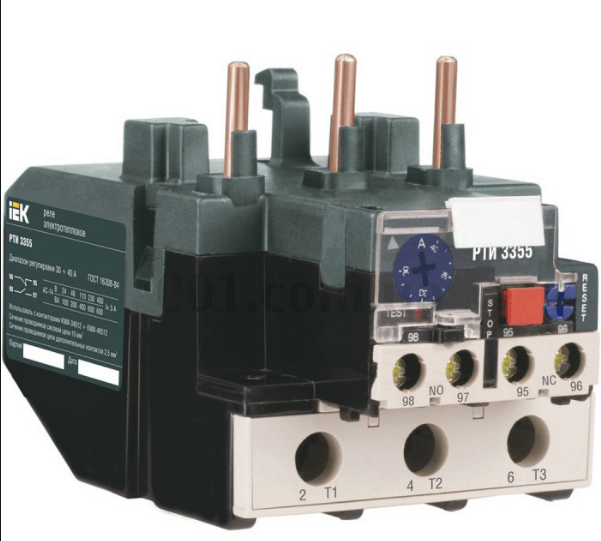

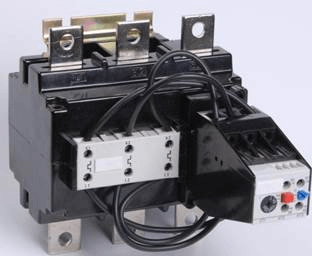

The photo below shows a section of the current apparatus. Through the conductors passes three phases of power to the electric motor. The heating coil is located on top of the bimetallic plate to reduce false response from external influences. The plates abut against a movable bar that pushes the release mechanism. On top is the spring regulator of the current installation, for fine-tuning the operation limits, and two groups of contacts (open NO and closed NC).

Principle of operation

What the thermal relay looks like you have learned, now we go further and tell how this device works. As we said earlier, RT protects the engine from prolonged overload.

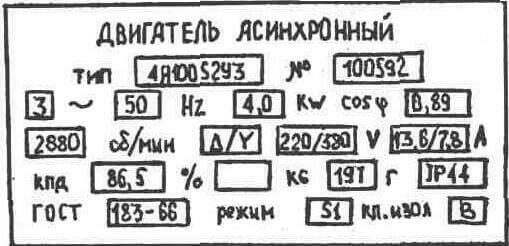

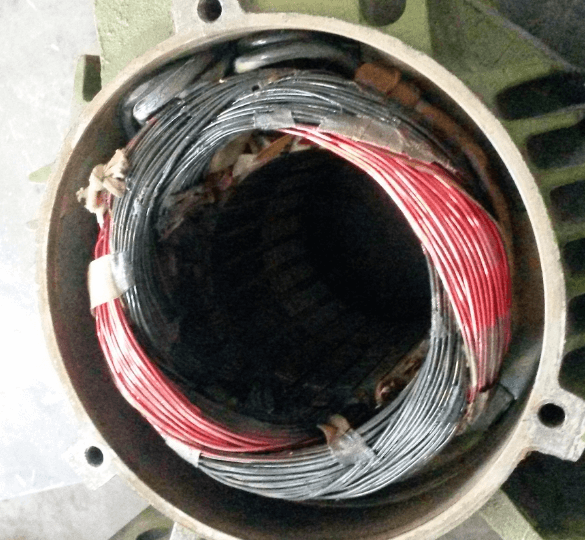

Each motor has a rating plate with the rated operating current. There are mechanisms in the operation of which an excess of the operating current is possible, both during startup and in the working process. With prolonged exposure to such overloads, overheating of the windings, destruction of the insulation, and failure of the motor itself occur.

This thermal protection relay is designed to act on the control circuit by disabling the circuit, opening the contacts, or by giving a warning signal to the personnel on duty, closing the contacts. The device is installed after the starting contactor in the power circuit in front of the electric motor in order to control the passing current.

Parameters are set upward from the rated current of the motor, by 10-20%, according to the passport data. Turning off the machine does not happen immediately, but after a certain time. It all depends on the ambient temperature and the overload current, and can range from 5 to 20 minutes.An incorrectly selected parameter will lead to a false response or ignoring overload and equipment failure.

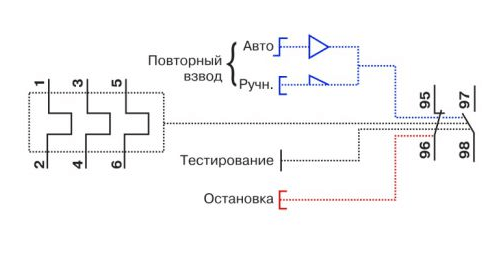

The graphic designation of the device in the diagram according to GOST:

You can learn more about how the thermal relay works and how it works by watching this video:

Appointment

Immediately I would like to say that there are various types and types of thermal relays and, accordingly, the scope of each classification is its own. Briefly talk about the appointment of the main types of devices.

RTL - three-phase, designed to protect the motor from overload, phase imbalancedelayed start or jamming of the rotor. PML starters are mounted on contacts or as an independent device with KRL terminals.

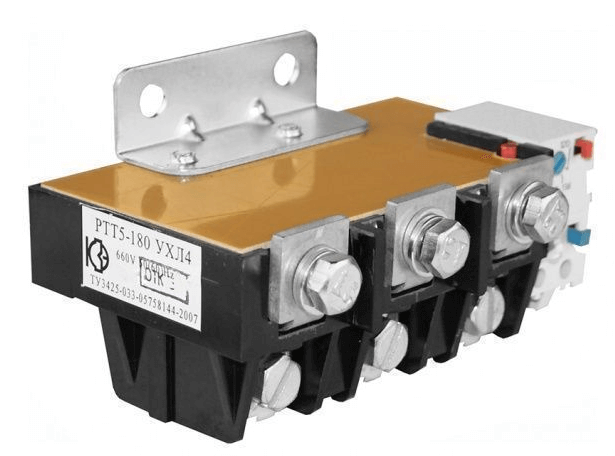

RTT - in three phases, designed to protect squirrel-cage motors from overload currents, phase imbalance, jamming of the motor rotor, prolonged start of the mechanism. Can be mounted on the PMA and PME starters, as well as independently installed on the panel.

RTI - protect the electric motor from overload, phase asymmetry, long start-up and jamming of the machine. Three-phase thermal relay, mounted on KMT and KMI series starters.

TRN is a two-phase relay that controls the operation and start-up mode, has only manual return of contacts, the operation of the device is little dependent on the ambient temperature.

Solid-state three-phase relays do not have moving parts, do not depend on the state of the environment, and are used in explosive places. It monitors the load current, acceleration, phase failure, jamming of the mechanism.

RTK - temperature control takes place with a probe located in the body of the electrical installation. It is a thermo relay, and controls only one parameter.

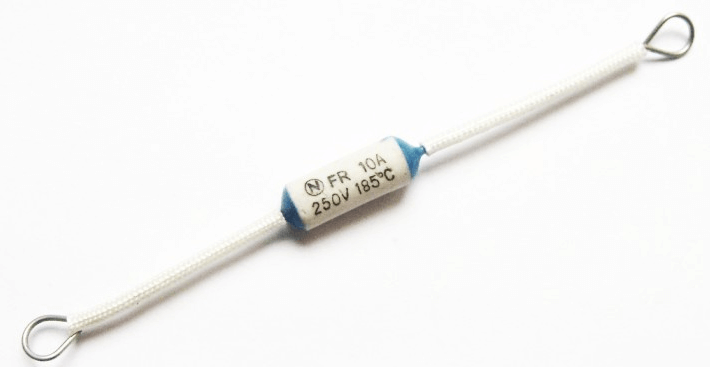

RTE is an alloy melting relay, an electrically conductive conductor is made of a metal alloy, at a certain temperature it melts and mechanically breaks the circuit. This thermal relay is integrated directly into the monitored device.

As can be seen from our article, there is a wide variety of control over the state of electrical installations, differing in type and appearance, but equally protecting electrical equipment. That was all I wanted to tell you about the device, the principle of operation and the purpose of thermal relays. We hope the information was useful and interesting for you!

It will be interesting to read: